-

-

The Makerpi's used in the BME department are customized. They run using Klipper firmware.

-

The Makerpi's use FFF (Fused Filament Fabrication) technology which extrudes molten plastic layer by layer forming a part.

-

Any questions or issues that arise should be directed to the BME Lab Director.

-

-

-

Log onto the BME laptop closest to the Makerpi printers using credentials provided at the top of the screen.

-

Open "PusaSlicer" as the slicer software of choice.

-

PrusaSlicer has great documentation which can be found here.

-

Upload the ".stl" file(or other compatible file type) by selecting the box icon.

-

If exporting from Onshape or other CAD software, make sure to select "millimeter" as the unit. If this is not done, the part will not be the correct size.

-

-

-

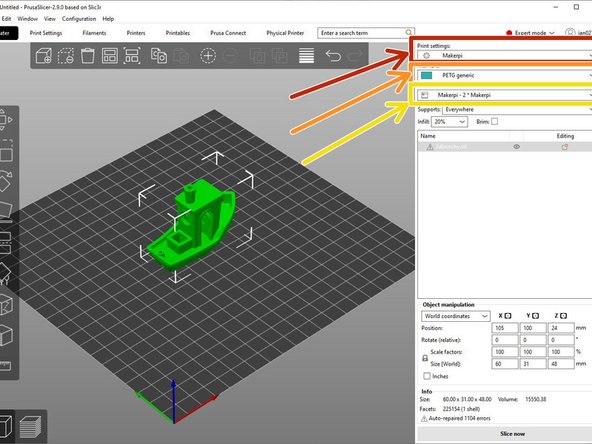

Verify "Makerpi" is selected under "Print settings"

-

Select the correct filament type.

-

If you are printing in the simulation lab (ACET 236), the only filament type is "PETG Generic".

-

A tutorial going through commonly used filament types is found here.

-

Select the printer's name using the drop down menu as shown under "Physical printers".

-

i.e. Makerpi - 1 or Makerpi - 2.

-

The printers name can be found underneath the LCD screen of the printer itself.

-

-

-

User interface basics for PrusaSlicer can be found here as needed.

-

Use the object manipulation tools for positioning, scaling, orientation and so forth as discussed in the Object Manipulation tutorial.

-

Placing an object perfectly flat on a build plate is necessary to avoid generating support material or printing difficult angles. More information can be found here.

-

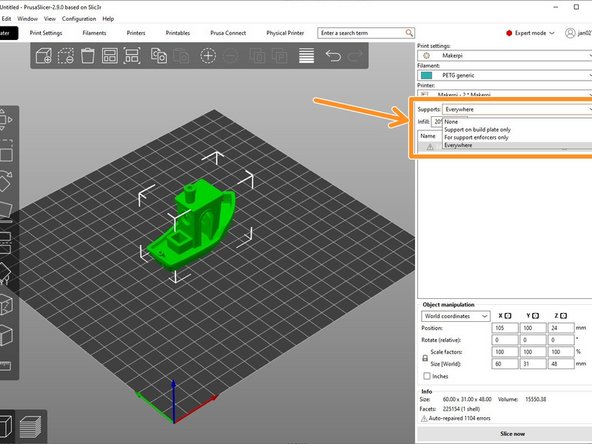

Modify the support material options which can be found below the printer selection as seen in the 2nd image. If in doubt, select "Everywhere".

-

For further information on support material and why it is needed, refer to the Support Material tutorial

-

-

-

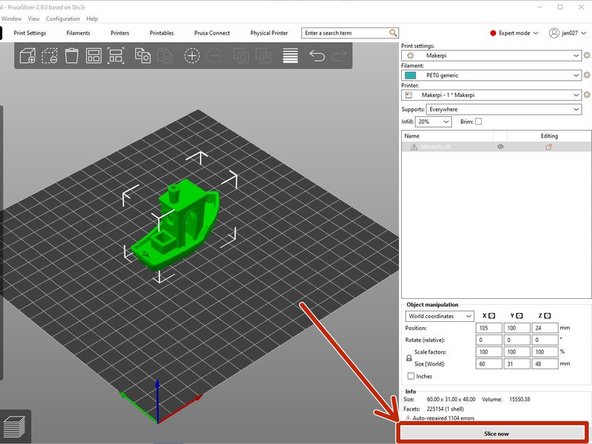

Once you are satisfied with the orientation of the part, select the "Slice now" button on the bottom right of the window.

-

Verify that the part on the screen is what you wanted.

-

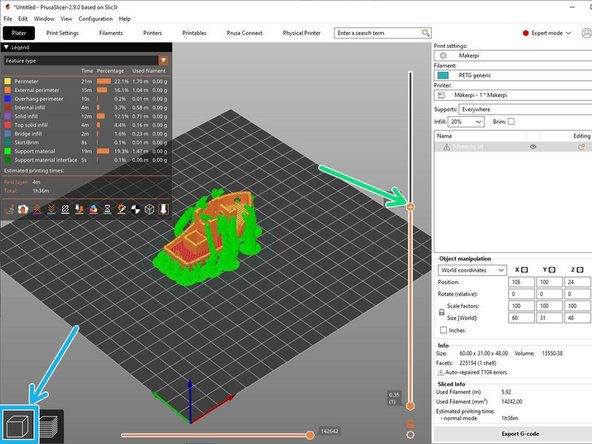

Layer cross section can be viewed by clicking and dragging the orange slide bars on the right side of the window as shown.

-

If further changes are needed, select the 3D box icon on the bottom left of the screen.

-

-

-

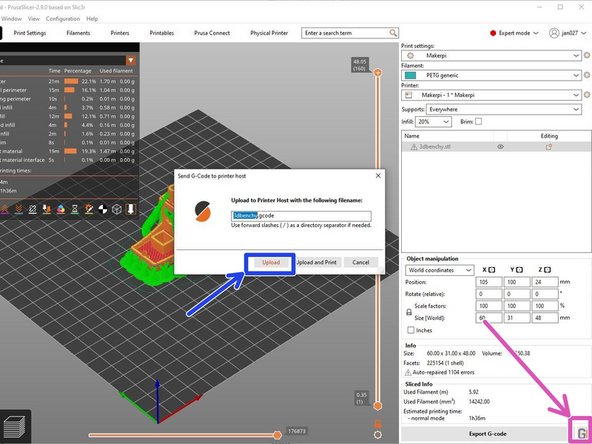

Once the file looks ready to print, select the "G" button in the bottom right of the window.

-

If the "G" button does not appear, the printer may have been selected incorrectly.

-

Rename file to something easily recognizable.

-

Select "Upload" to transfer the file to the printer automatically.

-

-

-

Clear off build plate on the printer from any material from previous prints.

-

The following steps can be skipped if printing in the Sim Lab (ACET 236). Otherwise continue with the steps below.

-

Load the correct filament type into the printer. A tutorial for changing filament is found here.

-

Note that flexible filament requires additional setup when loading and unloading filament.

-

Verify that the build plate matches the filament type being used. A tutorial on filament type and its compatible built plate type is found here.

-

-

-

Clear off build plate on the printer from any material from previous prints.

-

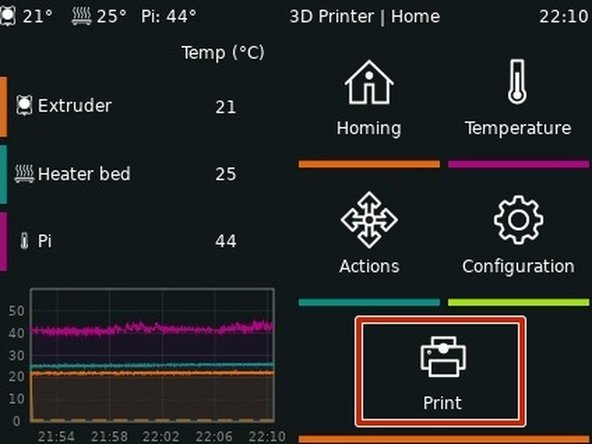

On the printers LCD screen, select "Print".

-

Navigate to find the uploaded file.

-

Date and refresh buttons may help.

-

If the file is not found. It may have been uploaded to the wrong printer. Check to make sure the correct printer has been selected within the slicer software.

-

Select print.

-

After verifying the selected file is correct, select print again to start the print.

-

Wait until the first layer prints correctly before leaving.

-

Almost done!

Finish Line