-

-

This filament changing tutorial is intended only for the Makerpi printers using common filament types such as PLA and PETG in the BME labs. Other printers or filament types may require different instructions.

-

Ventilation is required for certain types of filaments such as ABS, PC, Nylon and so forth. The filament used in the simulation lab (ACET 236) is and should only be PETG. For more information on filament types, refer to the tutorial.

-

If there are any questions or other comments, please contact the Lab Director.

-

-

-

Filament is defined as a thin (usually 1.75 mm in diameter) polymeric extrusion that is wound onto a spool.

-

A spool is a plastic cylinder which conveniently stores wound up filament.

-

A filament sensor notifies the printer when filament has run out or is not properly feeding through the extruder / hotend.

-

An extruder is a stepper motor and other hardware that drives the filament through the hotend.

-

The hotend heats up the filament until it can be extruded through a nozzle.

-

Note the color coordination of the images and definitions.

-

-

-

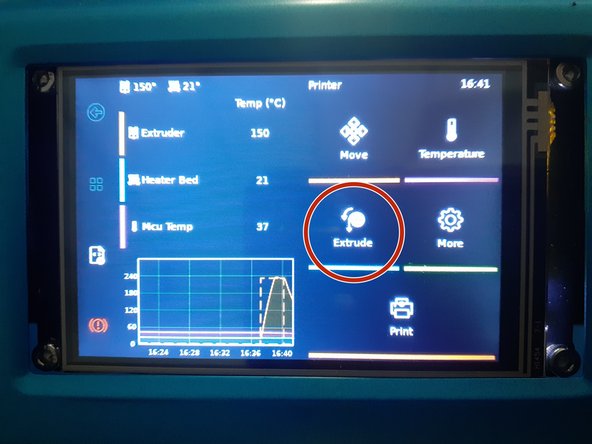

Navigate to the extrude screen

-

If the screen is on the main menu screen shown on the first image, select Extrude.

-

If the printer is paused, the current screen is the extrude screen.

-

If the screen is displaying "Print Complete", select Main Menu and then Extrude.

-

Select Unload.

-

Wait until the hotend reaches the target temperature and the filament is automatically pulled out of the extruder. This will take some time.

-

-

-

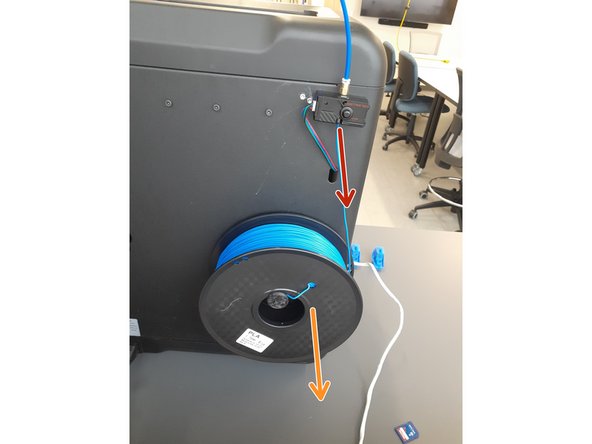

Once the automated unloading procedure is finished, pull out the filament from the PTFE tube until it exits the filament sensor.

-

Remove the spool of filament from the holder.

-

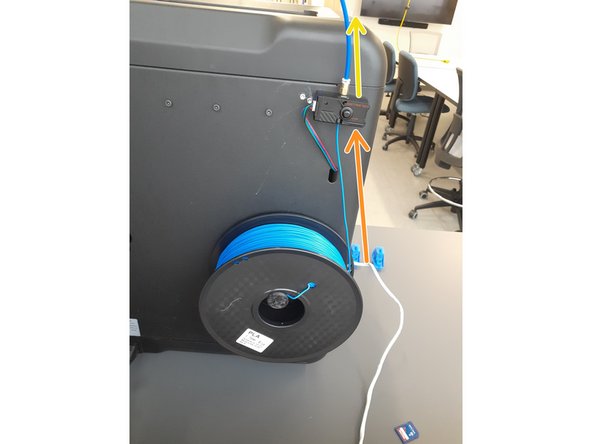

Secure the end of the filament through the side holes of the spool as shown in the third image.

-

Put away previous filament spool.

-

-

-

Grab a new spool of filament.

-

Take the end of the filament out of the holes that secured it.

-

Cut the end of the filament at a 45° angle.

-

This is optional but can make feeding the filament through the tube and other hardware easier.

-

Place the new filament spool on the holder on the back of the Makerpi in an orientation such that the filament can easily feed through the filament sensor.

-

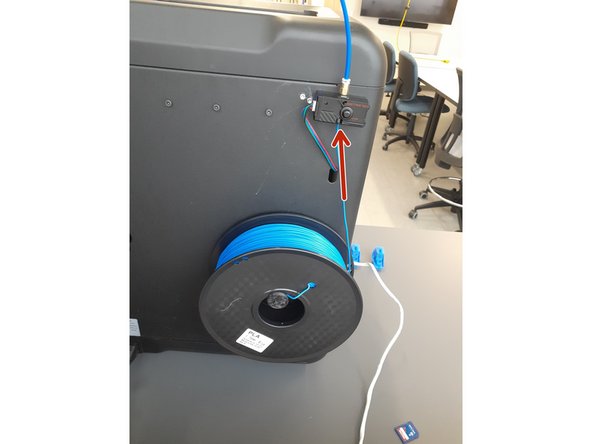

Feed the filament through the filament sensor and PTFE tube until it reaches the extruder.

-

-

-

Select "Load" on the touch screen. This again may take some time.

-

Once it reaches the correct temperature, create a slight inward pressure on the filament until the extruder grabs the end of the filament, pulling it in.

-

This step is optional and may not be needed but can help if the gears in the extruder are not able to grip the filament.

-

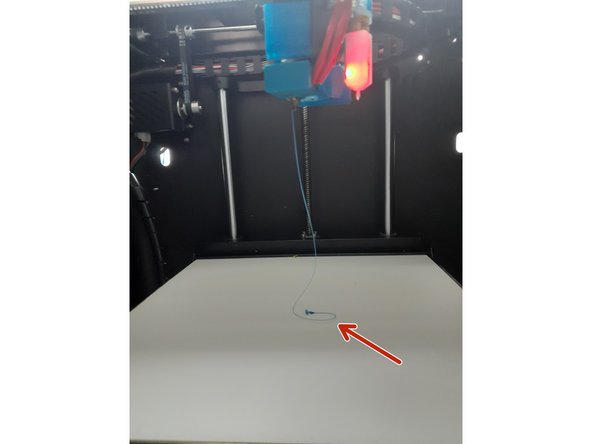

Watch for the polymer to extrude out of the nozzle to verify that you have successfully loaded the filament.

-

If the print was paused. Resume the print by selecting the back arrow on the top left of the screen and then select Resume.

-

If there are any issues, contact the Lab Director for assistance.

-

Almost done!

Finish Line