-

-

This tutorial is only an introduction to some of the filament options available.

-

The only filament type available in the Simulation Lab (ACET 236) is PETG. If another type is needed, ask the Lab Director.

-

Further information and resources can be taken directly from the manufacturer itself.

-

Parts of this tutorial were generated using Gemini AI.

-

-

-

For a polymer to be used by most 3D printers, it needs to be in filament form on a spool.

-

Additionally, the polymer needs to be a thermoplastic.

-

A thermoplastic becomes soft when heated and solidifies when cooled.

-

Adequate ventilation for 3D printers such as a ventilation system in a building is recommended for all 3D printing filament due to VOC's (Volatile Organic Compounds). However, some filament types are required to have more extensive ventilation.

-

Some filament types are hydroscopic, meaning it absorbs moisture from the air. Over time, filament that has absorbed enough moisture will become brittle, bubble, pop, exhibit stringing while printing, and loose mechanical strength. Because of this, it can also clog the nozzle.

-

A sign that filament has absorbed too much moisture is that it will easily break when slightly bent (Somewhat like dry spaghetti noodles).

-

-

-

There are many filament options but the following are used in most cases:

-

Polylactic acid (PLA)

-

Polyethylene terephthalate glycol-modified (PETG)

-

Acrylonitrile butadiene styrene (ABS)

-

Thermoplastic polyurethane(TPU)

-

Higher engineering grade filaments

-

Disolvable (PVA and HIPS)

-

-

-

PLA is one of the most commonly used filaments in FDM 3D printing.

-

This is because it is generally low in price, primarily derived from renewable resources like corn starch or sugarcane and is comparatively easy to print with.

-

However, PLA is only biodegradable in a specific industrial compost environment. Furthermore, additives from the manufacturer may or may not be biodegradable.

-

PLA is also comparatively brittle and will warp if left in a hot car.

-

-

-

PLA is extruded at around 200 deg C and does not usually require a heated bed or enclosed printer.

-

It is suggested to use textured build plates usually colored black in BME labs. Usually, buildtak flex plates are best. Do not use glue to increase the chance of PLA adhering to the build plate.

-

Normal ventilation for labs is considered safe, however continuous close proximity is not recommended.

-

PLA is also slightly hydroscopic so be cautious about using filament that has been exposed to the air for a long period of time.

-

PLA allows for bridging, sharper overhangs, and supports that are easier to remove.

-

-

-

PETG will be less likely to warp in a car due to heat and has a higher impact strength. Although it's tensile strength is not as good as PLA, PETG's slightly more ductile properties makes it generally more functional.

-

PETG is also chemical resistant and is quite similar to the plastic used to make disposable water bottles and other commonly used items. Because of this, recycled PETG filament is much more readily available.

-

Furthermore, PETG is used in industry for its food safety properties. However, in 3D printing, the PETG may not be food safe after coming into contact with gears, heated nozzles and a heated bed.

-

-

-

PETG is extruded around 235 deg C and does require a heated bed around 85 deg C. However, an enclosed printer is not needed.

-

PETG tends to adhere very well to a heated garolite build plate and detaches once cooled. Garolite sheets used in BME labs are not textured but rather glossy.

-

Normal ventilation for labs is considered safe, however continuous close proximity is not recommended.

-

PETG is also slightly hydroscopic so be cautious about using filament that has been exposed to the open air for a long period of time.

-

PETG can bridge like PLA.

-

With sharper overhangs, PETG tends to curl up.

-

PETG normally is stringy. This means a printed object can be covered in thin wispy strands of plastic.

-

-

-

ABS is a polymer commonly used in 3D printing and industry.

-

Its advantages are its strength, heat resistance, chemical resistance, and its ability to be sanded and smoothed with acetone.

-

ABS is commonly used in children's toys such as lego blocks because of its strength and non-toxic characteristics.

-

ABS however is difficult to print and requires ventilation due to toxic fumes generated during printing.

-

-

-

ABS is typically extruded at around 230 deg C, requires a heated build plate of around 100 deg C and also requires an enclosed printer.

-

ABS is most often printed on a PEI build plate as PEI becomes sticky at those temperatures. No glue stick is needed.

-

Additional ventilation is required for ABS since it releases toxic VOCs like styrene which is a known carcinogen.

-

ABS is also slightly hydroscopic so be cautious about using filament that has been exposed to the open air for a long period of time.

-

ABS is also very prone to warping which means it may detach from the build plate mid-print if caution is not exercised. This usually occurs within the first few layers.

-

-

-

TPU is elastic and so enables flexible objects to be printed. TPU is also quite durable, biocompatible and heat resistant.

-

For these reasons, you can find TPU commonly used in phone cases, footwear, gaskets, and medical devices.

-

TPU, however, can be difficult to print due to its flexibility and hydroscopic nature.

-

-

-

TPU is extruded at around 220 deg C. It may require a 50 deg C heated bed and does not require an enclosed printer.

-

TPU requires a textured build plate such as buildtak. No need for applying a glue stick.

-

Normal ventilation for labs is considered safe, however continuous close proximity is not recommended.

-

TPU is hydroscopic and will frequently need drying before printing for optimal results.

-

TPU requires a specialty printer including a direct drive extruder that is able to grip onto the filament well. There are more settings to verify such as speed, retraction and so forth.

-

-

-

There are many high performance 3D printing filaments which increase in strength and difficulty in printing.

-

These include Polycarbonate, Nylon, PEEK, Carbon Fiber reinforced and many others.

-

Each of these engineering grade filaments have an increased cost, safety issues and difficulty in printing.

-

For example, nylon is known for its strength which is why it is commonly used in rope. However, nylon produces toxic fumes while printing, has difficulty adhering to the bed and can warp easily.

-

Before printing with higher strength filaments, print with a more commonly used filament such as PETG or PLA. Then use the engineering grade filament after fully understanding the unique challenges of the more advanced filament.

-

-

-

3D printing occasionally requires printing support material. A further discussion on support material can be found here.

-

Dissolvable filament can mitigate the issues that support material causes.

-

However, muti-material printing capabilities are required such as a dual nozzle, tool changer or filament switching mechanism.

-

PVA (Polyvinyl Alcohol) is a water-soluble filament that PLA and other filaments adhere well to. It is also biodegradable. However, it is hydroscopic and requires a dry storage location.

-

HIPS (High Impact Polystyrene) is also dissolvable but only in limonene. HIPS is commonly used with ABS.

-

-

-

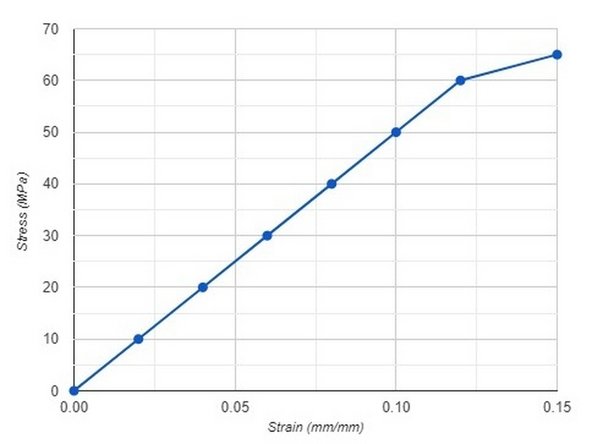

Material properties such as tensile strength or Young's modulus may be able to be found from certain manufacturers technical data sheet.

-

An example is MG Chemicals PLA data sheet which can be found here.

-

Another example is Polymakers PolyLite Pro which can be found here.

-

Estimated values can also be obtained using AI.

-

Almost done!

Finish Line