-

-

This tutorial is to be used as an introductory tutorial for use of the Fusion3 F410.

-

This printer has been rebuilt and is Klipper based.

-

Turn on the Fusion3 F410.

-

Tap screen to check if it is already on.

-

If it's not on, the power switch is located on the back right of the printer.

-

Verify the build plate is clean and clear from any previous prints.

-

Verify or load the correct filament into the printer. A Filament Options Tutorial is available when choosing a filament type.

-

Turn on ventilation if required due to filament type.

-

-

-

Verify or install the correct build plate which corresponds to the type of filament being printed.

-

Build plates are found below the printer, under the table.

-

For PLA, PETG, TPU and others, use the black Buildtak build plate.

-

For ABS, use the yellow PEI build plate.

-

For PC, use glass with a glue stick applied to the surface.

-

-

-

Log in to the computer near the printer using the credentials at the top of the screen.

-

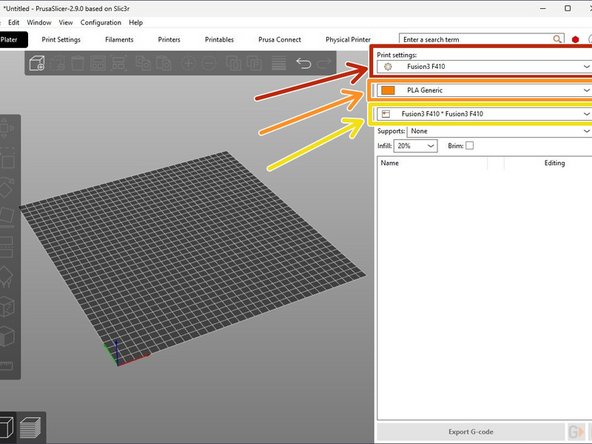

Open the slicer software. In this case, it will be PrusaSlicer.

-

PrusaSlicer Logo is shown in second image.

-

Documentation for PrusaSlicer can be found here.

-

Here is the link to the user interface documentation as needed.

-

-

-

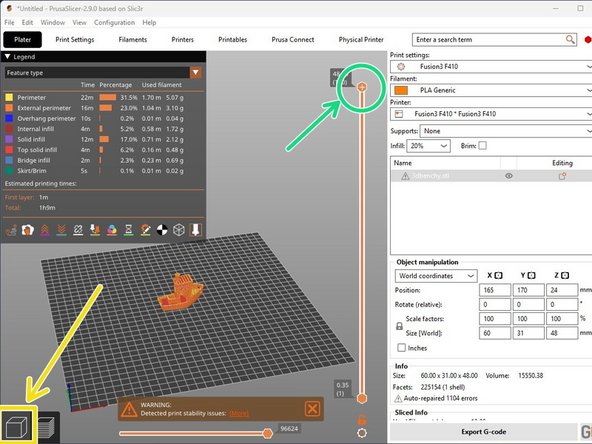

Verify "Fusion3 F410" is selected under "Print settings"

-

Select the correct filament type.

-

A tutorial going through commonly used filament types is found here.

-

Within the third text box under "Physical Printers", select "Fusion3 F410".

-

-

-

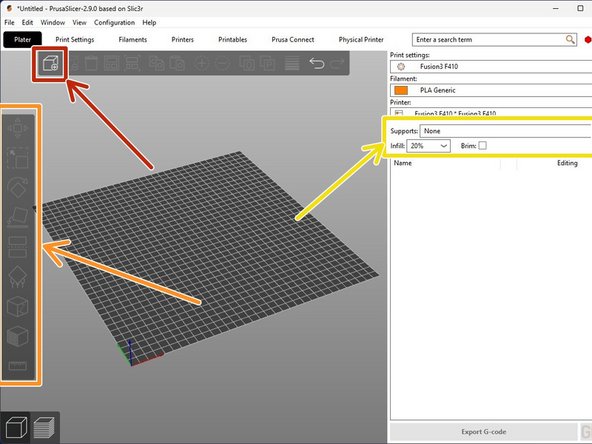

User interface basics for PrusaSlicer can be found here as needed.

-

To upload a stl file, select the box as shown in the image.

-

Use the object manipulation tools for positioning, scaling, orientation and so forth as discussed in the Object Manipulation tutorial.

-

Placing an object perfectly flat on a build plate is necessary to avoid generating support material or printing difficult angles. More information can be found here.

-

Modify the support material options which can be found below the printer selection.

-

For further information on support material and why it is needed, refer to the Support Material tutorial.

-

-

-

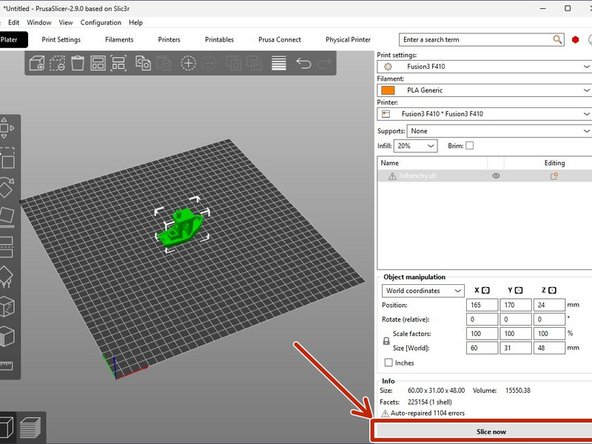

Once you are satisfied with the orientation of the part, select the Slice now button on the bottom right of the window.

-

After slicing is complete, PrusaSlicer will display a preview of the print as demonstrated in the second image.

-

Verify that the part on the screen is what you wanted.

-

Layer cross section can be viewed by clicking and dragging the orange slide bars on the right side of the window as shown.

-

If further changes are needed, select the 3D box icon on the bottom left of the screen.

-

-

-

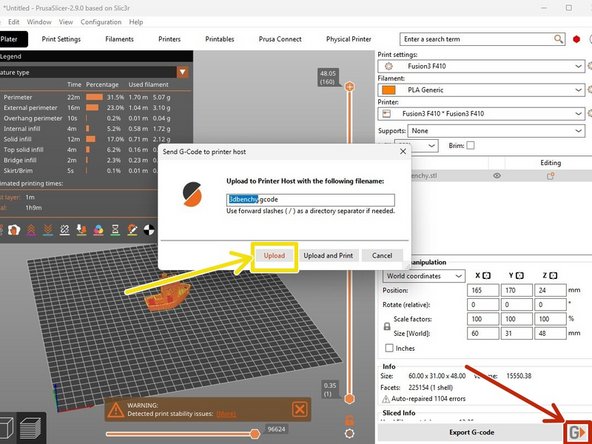

Once the file looks ready to print, select the "G" button in the bottom right of the window.

-

Rename file to something easily recognizable.

-

Select "Upload" to transfer the file to the printer automatically.

-

-

-

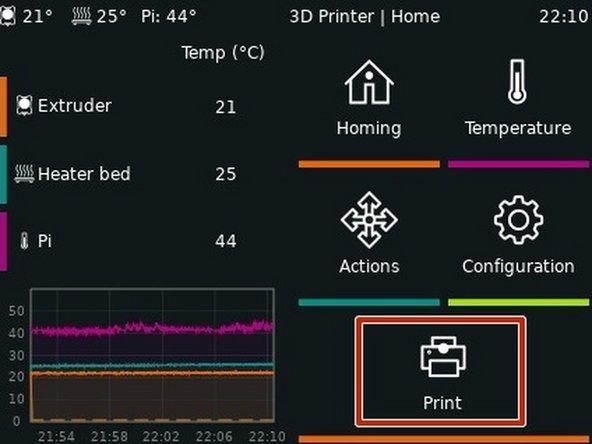

On the printer select Print.

-

Navigate to find the uploaded file.

-

Date and refresh buttons may help.

-

Select Print.

-

After verifying the selected file is correct, select print again to start the print.

-

Wait until the first layer prints correctly before leaving.

-

-

-

This printer requires periodic monitoring.

-

The user is expected to check on the printer every two hours.

-

If this is not possible, notify the Lab Director for further instructions.

-

If this is not done, access to the Fab Lab may be revoked.

-

Almost done!

Finish Line