-

-

This tutorial is an introduction to object manipulation within the slicer software Superslicer.

-

Because there are many factors that are in need of consideration, this is not a step-by-step tutorial, rather it is informational. Frequently the optimal orientation is up to the user and their preferences.

-

Further questions can be directed toward the Lab Director.

-

-

-

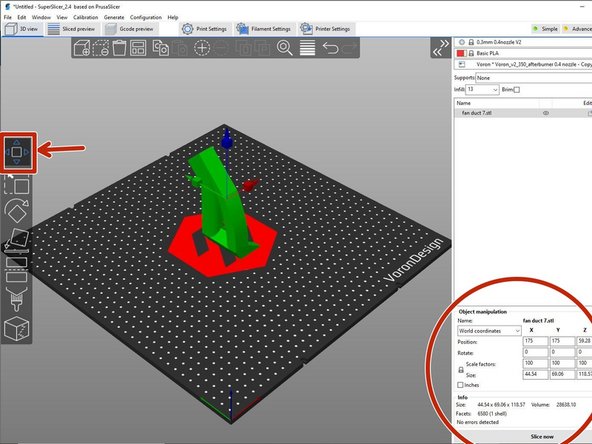

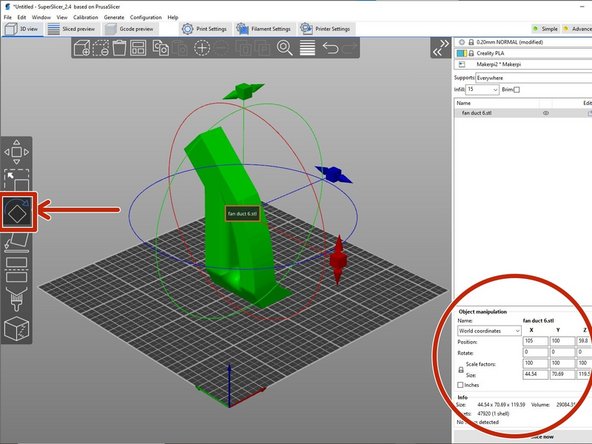

The object manipulation tools are found on the left side of the window. These include the following tools in order starting from the top: Move, Scale, Rotate, Place on Face, Cut, Paint-on Supports and Seam Painting.

-

There are additional tools which are located above the object. These tools may become useful in certain circumstances.

-

All tool names will appear when you hover the cursor over each tool button.

-

To use each tool:

-

Left click on the object highlighting it green.

-

Left click on the tool intended for use.

-

Deselecting the object can be accomplished by clicking an area where the object does not exist.

-

-

-

All objects on the build plate should generally be positioned in the center of the bed without intersecting any other objects.

-

To move an object around the build plate, simply left click and drag the object.

-

When moving the object along an individual axis, use the first tool "Move" as shown in the image.

-

To use this tool, click and drag the boxes that appear around the object.

-

For more precise control, you can type in a value within a text box. This is located near the bottom right side of the window in the section"Object manipulation".

-

An automatic arrangement tool can also be found on the top of the viewing window.

-

-

-

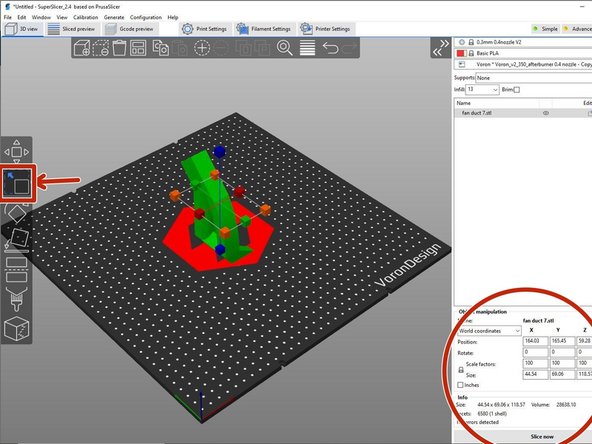

The second tool "Scale" is used to scale the object either uniformly or along a chosen axis.

-

Usually, scaling is not needed. If the object is not the size that is expected, go back to the CAD program (i.e. Onshape), and export the stl file in mm.

-

The "Scale" tool can be used by clicking and dragging the squares around the object.

-

The corner squares scale the object uniformly whereas the squares along each axis scales the object along that axis.

-

To reset scaling or provide more precise scaling, use the object manipulation section found near the bottom right of the window.

-

-

-

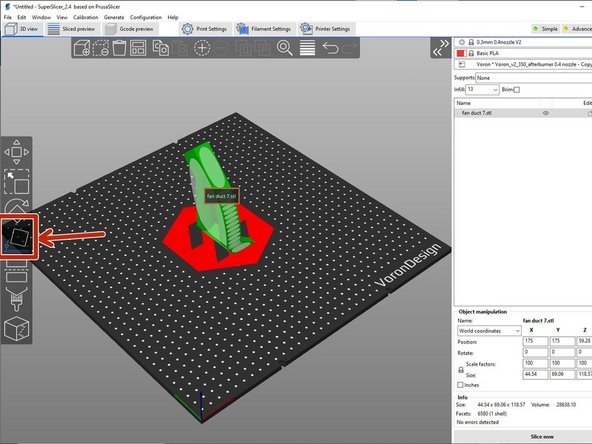

The 4th tool "Place on Face", is used to align a face with the build plate.

-

To use this tool, select the highlighted regions that appear on the object.

-

There are some considerations when choosing a face. These include:

-

support material, speed, surface texture, etc.

-

In most cases minimizing support material is the reason for choosing a certain face.

-

A discussion on what support material is and why it is needed can be found in the Support Material tutorial.

-

-

-

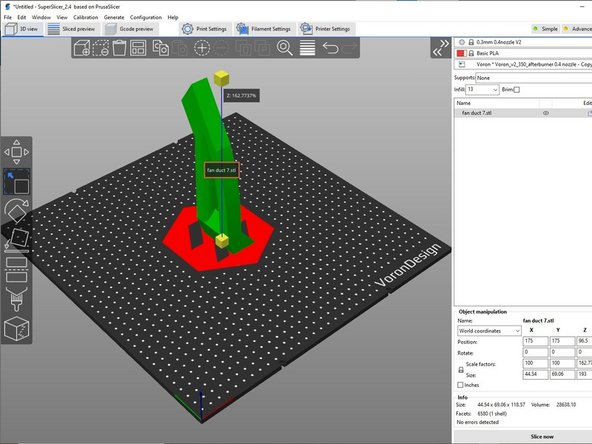

The 3rd tool "Rotate" is used when a particular angle orientation is needed rather than a particular face.

-

Note that using this tool will likely generate more support material as discussed in the Support Material tutorial.

-

To use this tool, click and drag one of the boxes appearing around the object to rotate the object around a desired axis.

-

As before, if an exact degree is needed, typing in the value into the corresponding text box within the Object Manipulation section will work as well.

-

-

-

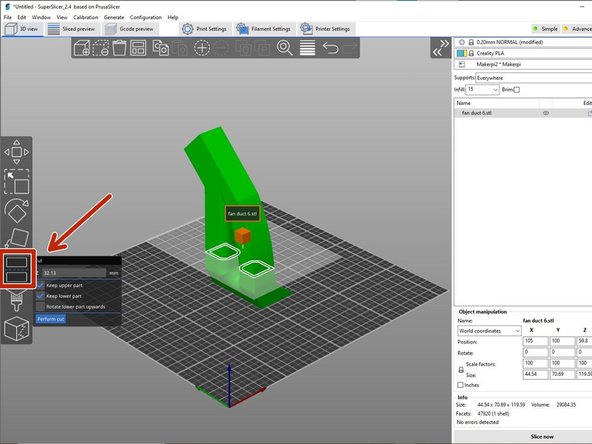

The "Cut" tool shown in the image is used to split the object in a chosen cross sectional z axis position.

-

To use this tool, click and drag the box for a visual location or type in a z axis position in the text box appearing next to the tool button.

-

Using this tool creates two objects that can then be manipulated separately.

-

This is useful when gluing the separate pieces together after the print is complete reducing the support material.

-

-

-

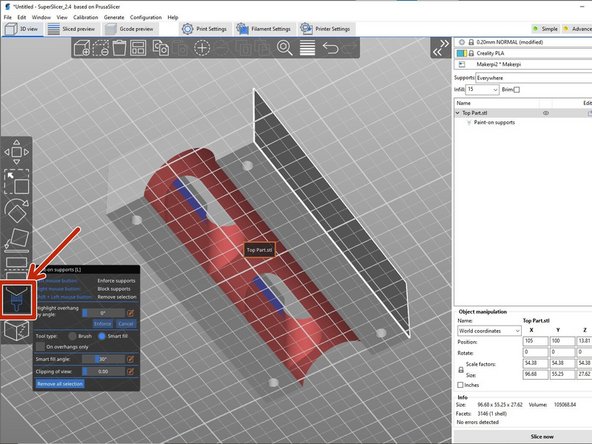

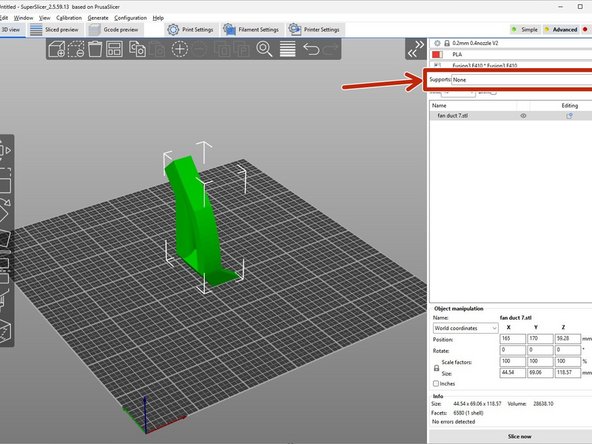

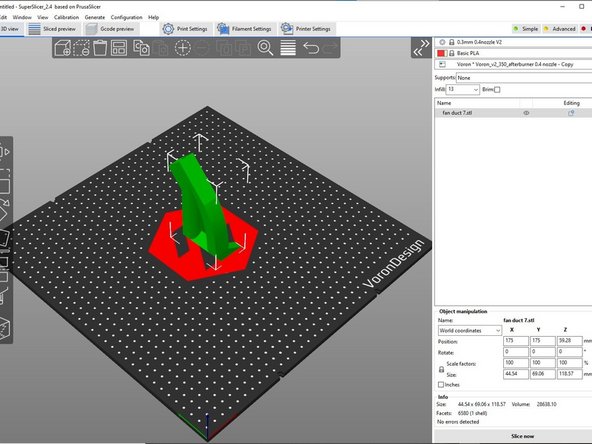

Normally, Superslicer automatically generates support material where its needed. Why support material is needed is discussed in the Support Material tutorial.

-

To control if and how automatic support material is generated, a drop down selection is found near the top right of the window just below the printer selection.

-

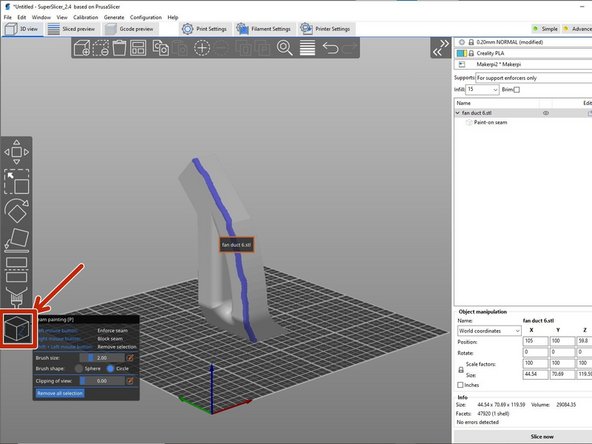

The tool "Paint-on Supports" can be useful if additional customization to support material is needed.

-

There are many options within this tool including manually painting on a surface "brush" or selecting a surface "Smart fill".

-

Left clicking highlights a surface in blue which indicates that surface should have support material.

-

In contrast, right clicking highlights a surface in red indicating that the surface should not have support material.

-

-

-

The tool "Seam Painting" is used to further refine surface imperfections.

-

On the outermost wall of each cross sectional layer the nozzle has a stopping and starting location. In this location a slight imperfection is created called a seam.

-

The seam location can be controlled using this tool.

-

Usually, the location for the seam is chosen on the back of an object where it is less likely to be seen or easily noticed.

-

-

-

As the user interacts with these tools, their usefulness increases.

-

This tutorial is only an introduction to the tools within Superslicer.

-

Any comments or questions can be directed toward the Lab Director.

-

Almost done!

Finish Line