-

-

Form 2 printer is a stereolithography (SLA) resin curing based 3D printer.

-

There are a few differences and similarities to SLA 3D printing when compared to the typical FDM printing

-

Simplistically, a 405nm violet laser cures resin layer by layer until a 3-dimensional part is produced. A video explaining further can be found here.

-

This tutorial will teach only the basics of resin printing to get you started and is not an all-inclusive guide to resin printing.

-

It is assumed that the user has a 3D model that fits within the Form 2 build volume and is a valid part file

-

-

-

log onto the BME Laptop in Fab lab using credentials provided at the top of the screen

-

Click on PreForm slicer icon as seen in image

-

Open 3d file within PreForm with a STL/OBJ/3MF file format

-

-

-

Roughly verify scaling of part by visually identifying size of object on the screen. If needed, scale your part

-

Orient your part so as to avoid cupping or other common issues by using the orientation icon

-

Autogenerate supports . Supports are needed in areas that would otherwise not be connected to the build plate or need extra support in order to print properly

-

-

-

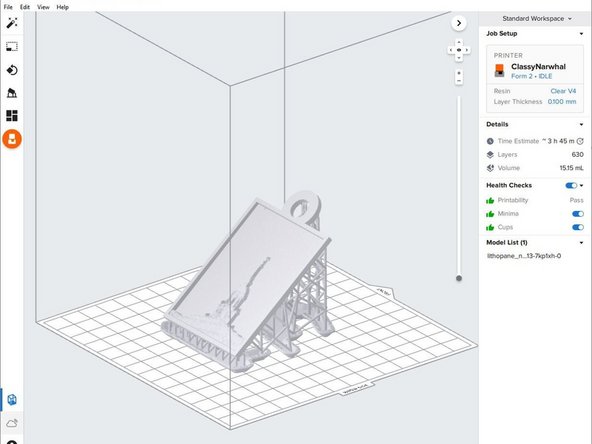

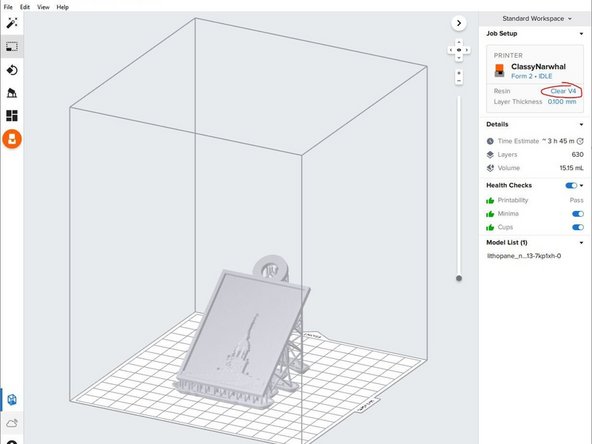

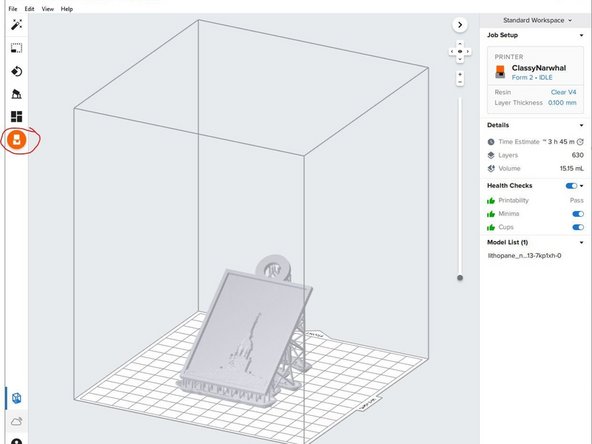

Verify printer is connected to PreForm slicer. The printer is named "ClassyNarwhal"

-

Verify the material type you intend to print with. The default material is the "Clear V4"

-

If another resin type is desired than what is currently in the printer, ask the Lab Director for assistance in changing the resin tank and resin cartridge

-

Transfer file to printer by clicking the orange print icon on the left of the screen

-

-

-

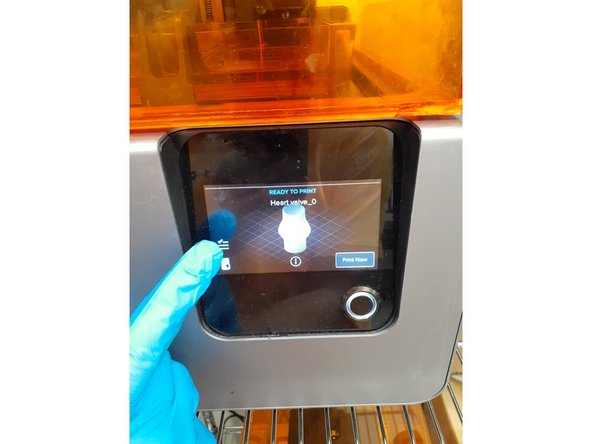

Before touching machine, put on PPE including safety glasses and gloves

-

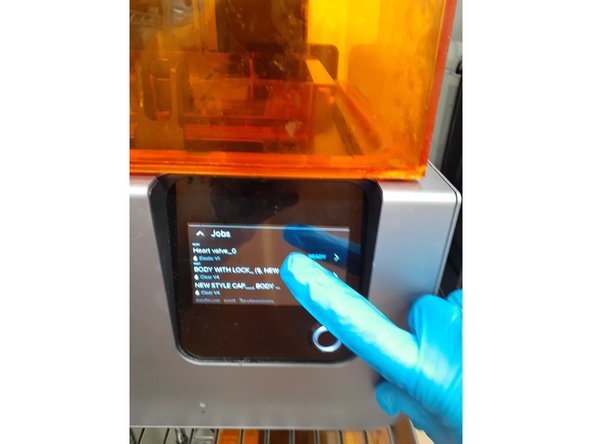

Find the file that you put on the printer via home screen

-

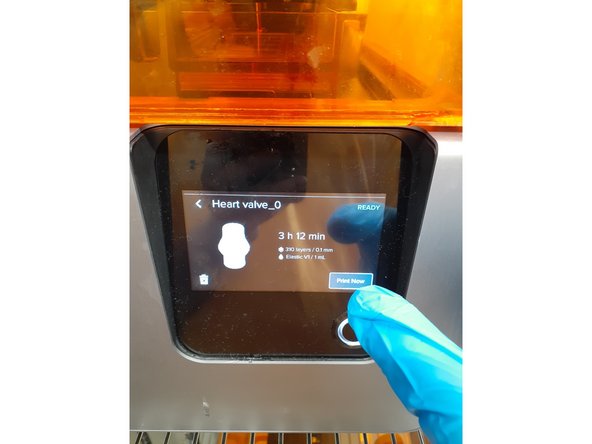

Tap Print Now. This will not immediately start the print. It will only begin the process and prompt you on next steps

-

-

-

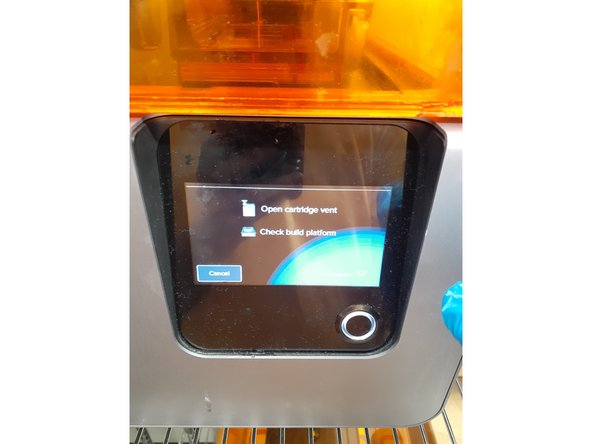

The screen will now show two items to verify before printing

-

Open cartridge vent as seen on the image to allow the printer to autofill with resin

-

Verify that the build platform is securely on the printer as seen in image

-

Press the push button to start the print

-

-

-

After a print is finished, it needs to be washed in Isopropyl alcohol.

-

Before transferring the part to the Form Wash, put on gloves

-

Please be considerate and mindful by cleaning up any resin that drips onto the floor or workspace.

-

A great video explaining washing of your part can be found here.

-

The specific settings for length and quantity of washes can be found here.

-

-

-

FormLabs provides cure times and temperatures in this chart.

-

Currently we do not have the FormLabs cure station but alternatively use an Elegoo Mercury Plus to cure parts

-

To use the cure station follow these steps:

-

remove lid

-

place washed part on stage

-

replace lid

-

add cure time according to FormLabs chart (15-30 min for clear)

-

start curing procedure by pushing play

-

Almost done!

Finish Line