-

-

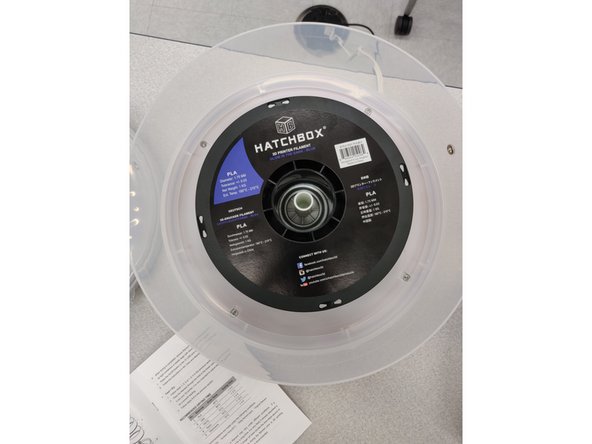

All 3D printer filaments are made of polymers, which are prone to absorbing moisture

-

Moisture in the filament can lead to issues such as:

-

Reduced part strength

-

Reduced layer adhesion

-

Uneven extrusion lines

-

Uncharacteristic blobbing, oozing, or stringing

-

Textured or "fuzzy" surfaces on the print

-

If you are getting prints which look something like the chair in the image, drying your filament can help improve the quality of your prints

-

-

-

We solely use PLA in the Maker-E and PLA has a glass transition temperature of 70 degrees C

-

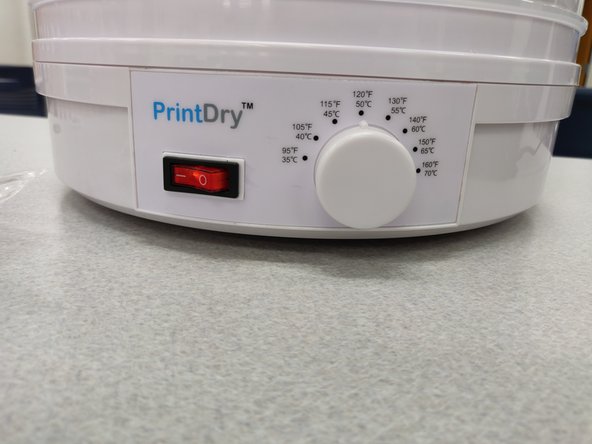

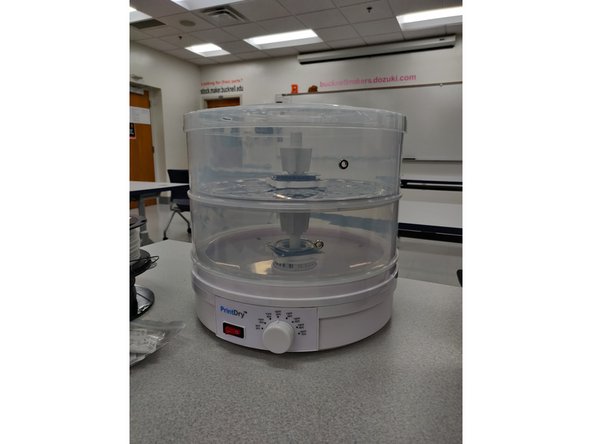

Set the temperature of the dryer to 50 degrees Celsius by turning the knob to the appropriate setting

-

50 degrees Celsius gives us a good margin of error for the temperature while still maintaining good drying conditions

-

Do not set the temperature higher than 50 degrees, doing so can cause the filament to get soft and melt together which will ruin the roll

-

-

-

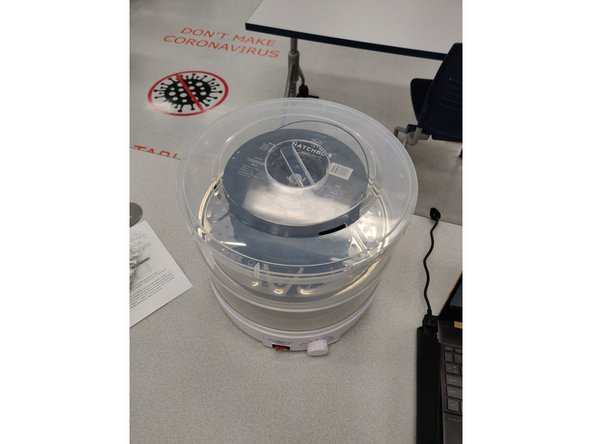

Up to two rolls can be dried at once

-

The first roll is inserted on the bottom layer

-

Align the filament on the metal bracket

-

Place the white alignment jig over the white pole to ensure the filament is secured

-

Notice: the alignment jig should be placed on the rod with the narrower side first

-

-

-

Add the second level of the print dry

-

Place the second roll of filament just as you did with the first roll

-

Place the cover on the PrintDry

-

-

-

Flip the switch on the dryer to the on position

-

You should hear the dryer turn on

-

If not, check to see if it is plugged in properly. The plug is polarized and will only insert a certain way

-

If you still do not hear the dryer turn on, please notify a technician or Matt.

-

-

-

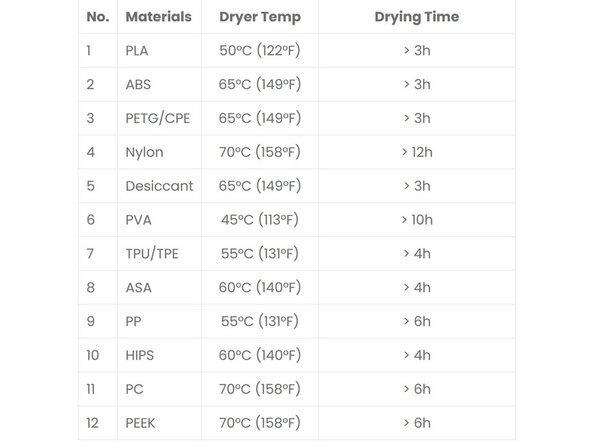

Typical drying times for PLA filament is around 3-4 hours

-

Longer dryer times can be utilized to remove even more moisture

-

Warning! Never use the filament dryer longer than 40 hours straight. This could damage the equipment.

-

Set a timer for the amount of time you're going to be drying the filament using a timer next to the 3D printers

-

-

-

Don't forget about the filament while it is drying! The PrintDry does not have an auto-off feature

-

-

-

When the filament has finished drying, remove it from the device and turn it off.

-

Make sure to rebuild the device cavities and to place the cover back on top

-

Cancel: I did not complete this guide.

13 other people completed this guide.