Introduction

This guide will teach you how create a custom tee shirt using the Heat Nation press. It requires you already know how to use the vinyl cutter.

The shirt press gets dangerously hot so please use caution!

-

-

The press takes some time to warm up so turn on the orange rocker switch on the back, left side of the press first.

-

Caution! The press gets hot and the bottom side of the upper plate can give you serious burns. Be careful!

-

-

-

Every type of vinyl has a particular temperature and press time. We stock Sizer Easy Weed vinyl which has a set temperature of 305 F.

-

Read the green numbers on the display to see the set value (SV) for the temperature. If you are using a different vinyl or it is not 305 you need to set it for the vinyl you are using. In this picture the setting is 330 F.

-

While the time for Sizer Easy Weed is 15 seconds we find a time of 25 seconds works better which should be the default setting for the press. Here the time is 18 seconds as shown in the green numbers on the right.

-

The actual temperature of the top plate and time left are shown in blue numbers with the labels PV for process value.

-

If the settings are not correct the next step shows how to change them. Otherwise skip ahead.

-

-

-

Skip this step if you don't need to change the settings of the heat press.

-

To change the settings press the OK button.

-

The first thing to set is the temperature units. Make sure F is selected.

-

Press OK.

-

Now set the Set Values (SV or green numbers) for the temperature using the up an down arrow keys for the vinyl you are using.

-

Press OK.

-

Do the same for the time using the arrow keys then press OK

-

Remember standard Easy Weed vinyl is 305 F for 25 seconds.

-

-

-

Unless you are doing thick or thin fabric you should skip this step!

-

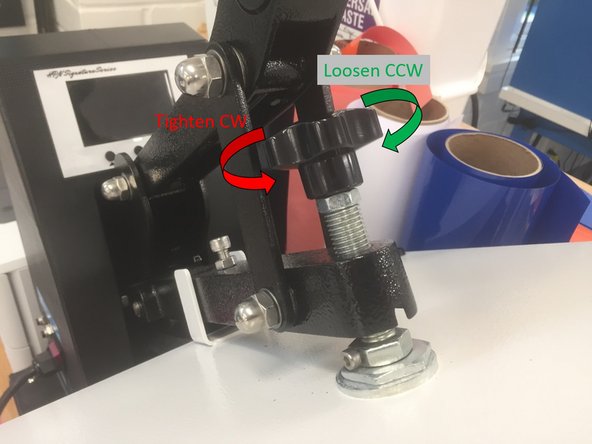

The screw knob on the top plate is used to adjust the pressure. Too little and the vinyl won't stick. Too much and you can't close the press.

-

If you need to adjust the pressure put a piece of paper on the bottom plate and close the press.

-

It should be hard, but not impossible to pull the paper out without tearing it.

-

If it is easy to pull the paper out then turn the know clockwise to increase the pressure. If the paper can't be pulled out turn the knob counter-clockwise to reduce the pressure.

-

Repeat the above step until you get the pressure right.

-

-

-

While the press is reaching its correct temperature you'll need to prepare the vinyl.

-

The vinyl cutter is used to cut shapes just as in making decals. See the vinyl cutter tutorial.

-

DO NOT use sticker vinyl to make shirts. A special shirt vinyl that has a shiny backing layer is used instead.

-

When you are cutting tee shirt vinyl make sure the shiny side (which is the backing) is facing DOWN on the vinyl cutter and the dull side is facing up.

-

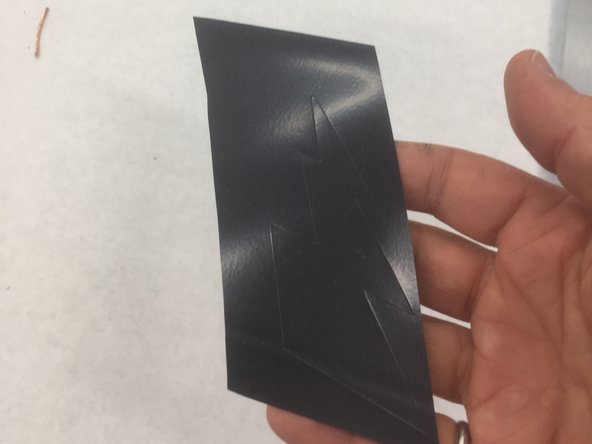

The first image shows the reflection from the shiny side and the second from the dull side.

-

Images and text MUST be mirror imaged (flipped left to right) to show up properly on a shirt. You can do this with the original image or do it on the vinyl cutter.

-

The cutting settings used for decal vinyl should work just fine for tee shirt vinyl.

-

-

-

Use tweezers or a sharp object to remove the vinyl you don't want.

-

When you are done you will have the shape to put on the shirt attached to a transparent sheet as shown.

-

The sticky side of the transparent sheet will go face down on the shirt or other object you are making.

-

Make sure the dull side is down and the shiny side is up on your shirt!

-

-

-

Make sure the press has come to the set point - the green SV and blue SV values are the same.

-

Pull out the bottom sliding stage.

-

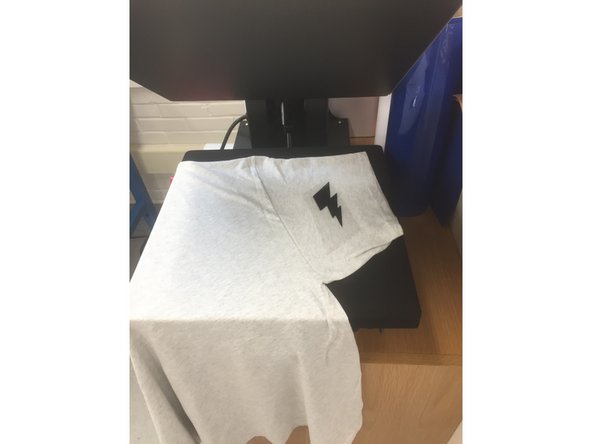

Carefully put the shirt on the bottom stage, being careful not to touch the hot top plate.

-

The second image shows the shirt on the bottom plate with the lightning bolt vinyl arranged on a shirt sleeve.

-

Make sure the cloth is flat with no wrinkles, especially under the vinyl!

-

-

-

It is better to put all the vinyl pieces that fit in the 16" x 16" area of the press on the shirt at once rather than do them one piece at a time.

-

Make sure that the vinyl pieces are well aligned to the shirt and each other before going to the next step.

-

Pressing is permanent, you can't easily pull the vinyl off once you make the shirt so take the time to get it right before moving on.

-

-

-

When you have the vinyl aligned put one of the brown protective films over the top of the shirt to protect it from the hot press.

-

DO NOT PRESS WITHOUT THE PROTECTIVE SHEET!

-

Slide the drawer in.

-

Press down HARD but gently on the handle until the press locks into place. You will hear a loud snap.

-

As soon as you move the top handle the timer will start, so push down fairly quickly and don't hesitate.

-

-

-

As soon as you start to lower the handle the green PV timer will count down and start to beep with three seconds to go.

-

When the timer reaches zero pull up firmly but gently on the handle to unlock the top plate. Raise it up fully.

-

Before removing your shirt slide out the drawer for safety.

-

The shirt is hot so wait a few seconds before taking off the shirt.

-

-

-

Peel off the transparent backing layer when the shirt is cool enough to do so.

-

Your shirt is done!

-

If the vinyl peels up while removing the clear adhesive film first check the settings to make sure they match your vinyl. If they are right then press the design a second time.

-

Now that you have some vinyl on the shirt you can layer it for an applique look or add new designs to the back or the sleeves

-

The next steps describe how to put vinyl on the back of a shirt or how to layer designs.

-

-

-

The process of putting vinyl on the other side of a shirt is exactly the same except there is one more important step.

-

Before putting a tee shirt with vinyl on the bottom stage you MUST put one of the brown protective sheets on the bottom, cloth stage!

-

This keeps the vinyl from sticking to the cloth on the bottom stage and ruining the stage and your shirt.

-

-

-

If you want vinyl on top of vinyl you have to do it in two steps.

-

First press the bottom vinyl to the shirt.

-

Remove the clear protective layer then place and align the second vinyl image on top of the existing vinyl.

-

Otherwise the process and settings are exactly the same.

-

-

-

The image shows some common temperature settings and time settings for vinyl.

-

Note it generally does not hurt to increase the time by about ten seconds.

-

-

-

When you are done making shirts make sure to turn off the press using the switch on the side.

-

Clean up your mess putting the extra vinyl pieces in garbage rather than recycling.

-

Report any damage to the machine or difficulties to the MakerE techs.

-

-

-

You can buy shirt vinyl in small quantities at Michaels down in Shamokin Dam.

-

For larger quantities at much better prices we order from Heat Press Nation.

-

We typically useSizer Easy Weed vinylwhich comes in many colors.

-

But manyspecialty vinyls such as glitter, metallic, or fluorescent can be ordered.

-

We have had good luck buying shirts from Tee Shirt Wholesalers.

-

At the end of this tutorial you will be able to make custom tee shirts.

At the end of this tutorial you will be able to make custom tee shirts.