Introduction

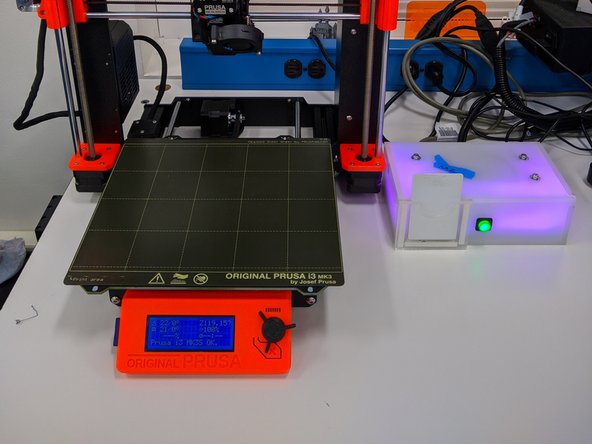

The Prusa i3 MK3S+ is a 3D printer used to create physical three-dimensional objects from 3D computer models. Plastic is the most typical medium. While this printer is capable of printing many different types of plastic, we ask that you only use PLA or PETG. The basic function of a 3D printer is almost like a computer controlled hot-glue gun that follows certain patterns generated by horizontally slicing 3D models into layers. The hot end assembly of the printer draws each layer by extruding filament onto the print bed. After all the layers build up, the object is complete! If you would like to learn more about 3D printing or have difficulties with a project the “A-Z 3D Printing Handbook” is a comprehensive manual that discusses many of the issues of getting good 3D prints. You can access the PDF file attached to the bottom of this guide.

Published by Ryder R. Nance with contributions from Matt P. Lamparter.

-

-

Please keep the Maker-E clean! There are several vacuums you may use to clean debris out of the 3D printer’s enclosure. You can find these in a labelled cabinet.

-

The nozzle (hot end) of the printer gets very hot in order to melt the plastic filament. To avoid burning yourself, do not touch the nozzle while the printer is running, or immediately after a job has finished. Note that the print bed will also get hot.

-

3D printers are able to print multiple types of plastic. Most printers in the Maker-E are restricted to PLA only. The Prusa is able to work with PETG as well. If you wish to use ABS, please visit the Mooney Lab or 7th Street makerspaces.

-

Because you will be logging in to the computer using a local account (not your Bucknell credentials), you will not be able to access your PRIVATE netspace account. Public netspace accounts will be accessible, as well as email and Google drive.

-

The 3D printers are not for printing boxes or any high-cost material print that can be easily achieved by other methods, such as laser cutting. If you believe your print is an exception, please email Matt Lamparter, ECE Lab Director and manager of the Maker-E, with a copy of your design and a justification via mlampart@bucknell.edu.

-

For box creation using laser cutting, users can use this tool to generate SVG files: https://festi.info/boxes.py/

-

-

-

Note whether PLA or PETG filament is loaded on top of the printer. You will need to configure your print for this filament later.

-

You can check the filament type by referring to the label on the side of the filament roll.

-

-

-

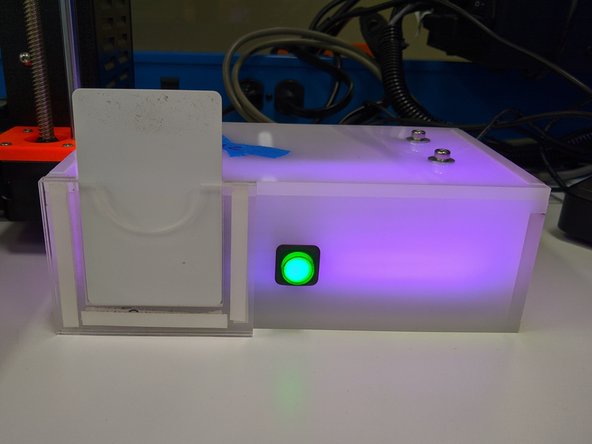

Speak with a Maker-E tech to have them temporarily authorize you to train on the printer. They will help you authorize the Portal box to turn on the printer. The Portal box should turn purple to indicate training mode.

-

Confirm that the printer powers up.

-

-

-

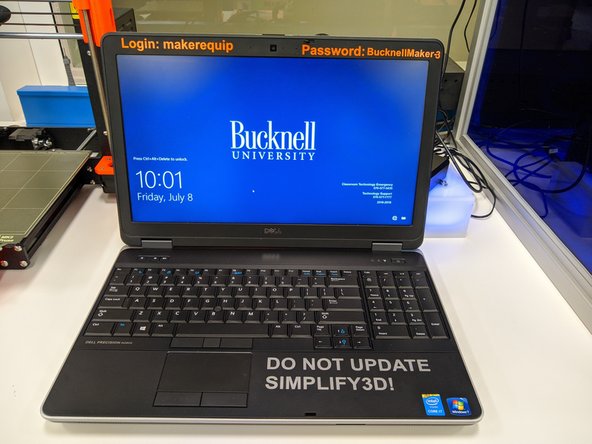

There are two laptops in the Maker-E used exclusively for 3D printing. Please use one of these two laptops to generate your print file.

-

Once the printer powers up, continue by logging into the laptop using the following credentials:

-

Username: makerequip

-

Password: BucknellMaker-3

-

Note that while you can still log in to the computer using your Bucknell credentials, the printer will not function properly this way - your print mail fail or you may damage the printer.

-

When logged in using the above credentials you will not be able to access any files in your private Netspace. Your file(s) should be accessible via public Netspace, Google Drive, email, physical media, etc.

-

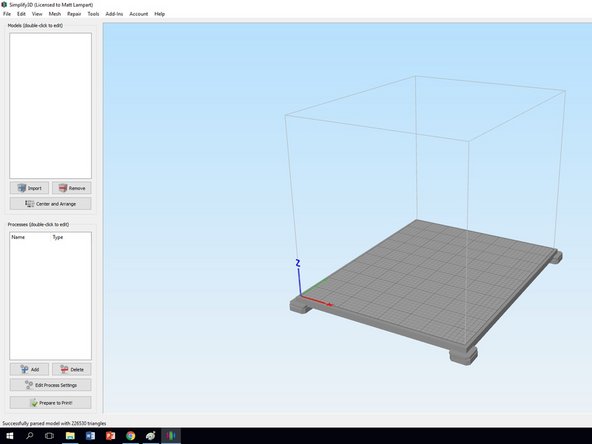

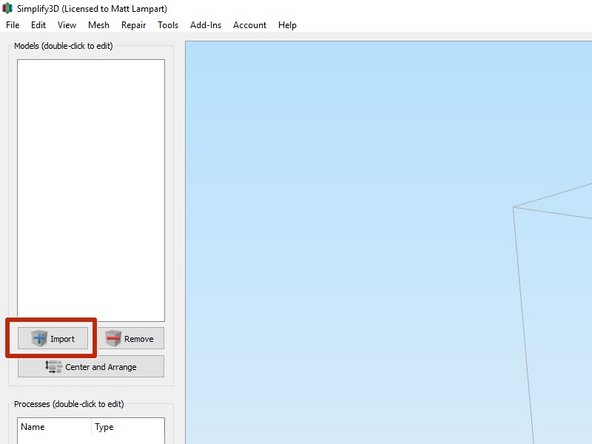

Launch the Simplify3D application by double clicking the shortcut on the desktop.

-

After Simplify3D opens you should see the screen shown here. If you encounter a login screen, please stop and see a technician.

-

-

-

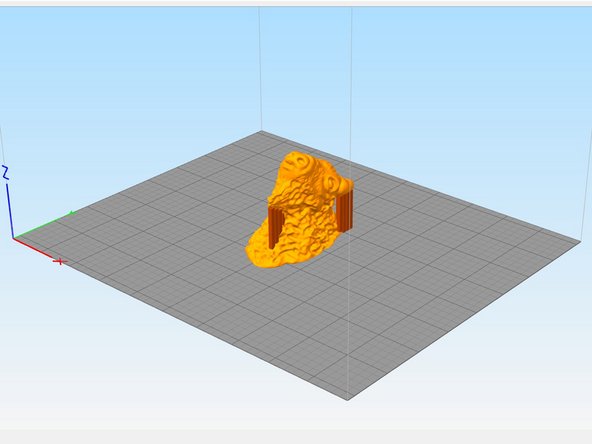

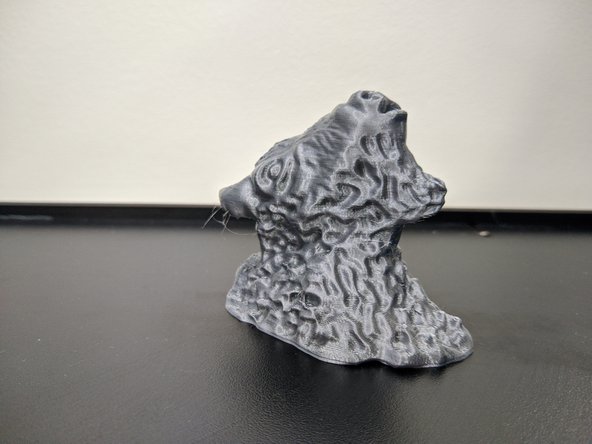

If you are using the printer for the first time to pass your certification then download the bisonHead.stl file attached to the bottom of this guide. This file came from Thingiverse, which is a great resource for free 3D object files.

-

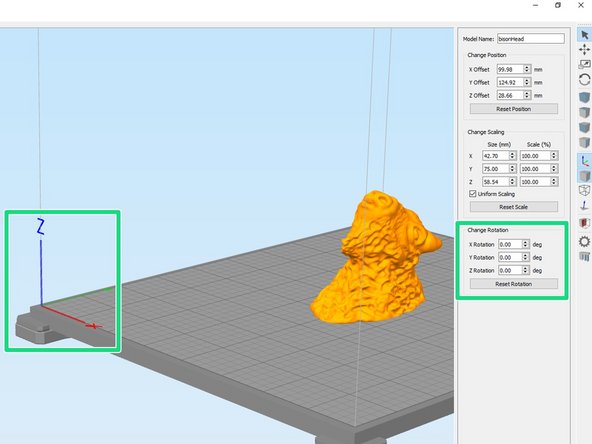

Click Import and navigate to where your STL file is saved. After you have imported your file, experiment with using the mouse to navigate the workspace. Zooming, rotation, and translation are all possible with the scroll wheel, left button, and right button, respectively.

-

The orientation of your object may affect how much support material is needed. More on this later. The basic idea is to rotate your part so that as much flat surface area sits on the print bed as possible.

-

You can change the rotation by double clicking the object then adjusting the rotation settings as needed. The bisonHead.stl object has a flat bottom which is already resting on the print bed. Thus, it does not require any rotation.

-

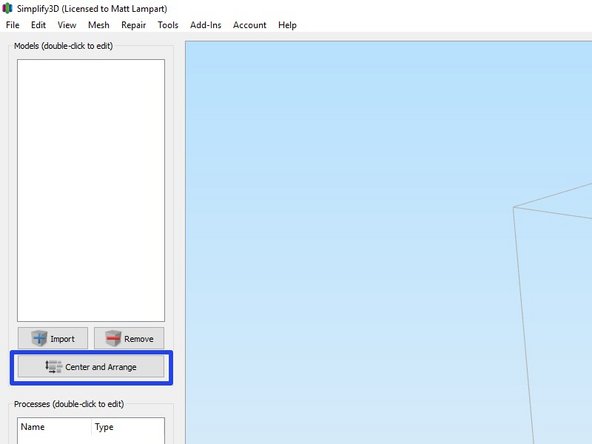

If you rotated your model, click Center and Arrange to reposition your model in the center of the print bed and drop it flat on the surface.

-

-

-

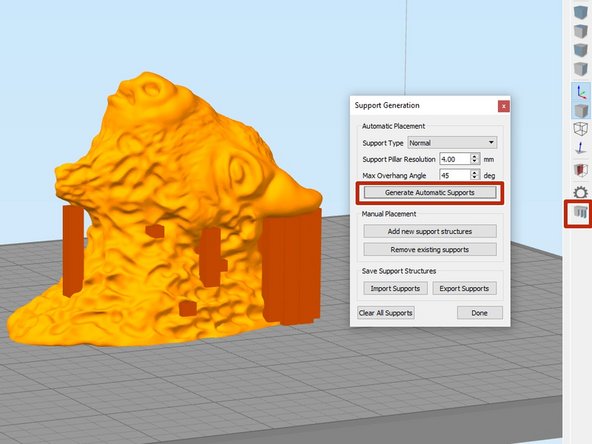

Notice how the bison's horns and chin stick out from the head, with nothing underneath them? If the printer tried to print these as shown it would be extruding hot plastic in midair - which would promptly fall! We call this overhang.

-

The solution is to define "support material" underneath these overhangs which will give the printer something to rest the overhangs on while they are being printed. Support material is generated in such a way as to provide good support while printing, but can be easily removed once the print finishes. Support material is temporary.

-

Begin by clicking the stonehenge-looking icon on the right to bring up the Support Generation window. Click the Generate Automatic Supports button to have Simplify3D add supports where it deems necessary.

-

-

-

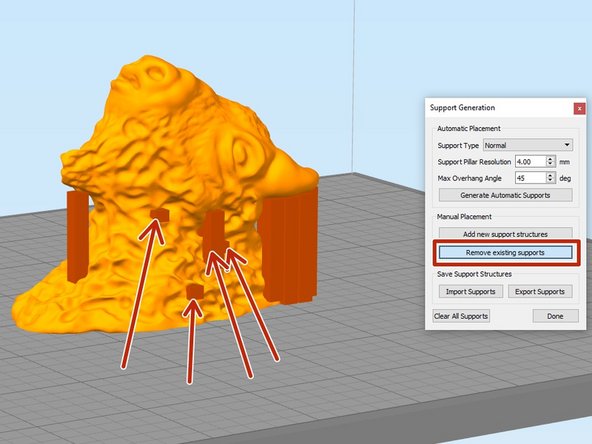

Simplify3D does a pretty good job at placing support material, but it is important to examine the automatic placement and think about how the resulting model will print. In this example, there are several areas where support is not needed and will only make for difficult removal. These are called out in red.

-

Click on the Remove existing supports button and then left click on all of the supports you wish to remove. Remember to check both sides of the model!

-

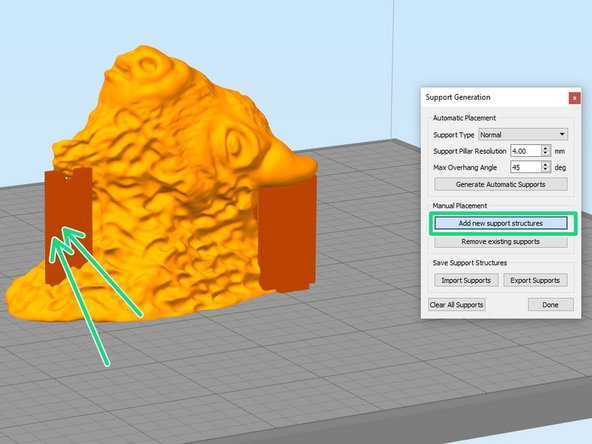

You should also add several additional supports for the chin to ensure it prints properly. These are called out in green.

-

Click on the Add new support structures button and then left click where you would like to add support.

-

Click Done to exit support definition when you are satisfied.

-

-

-

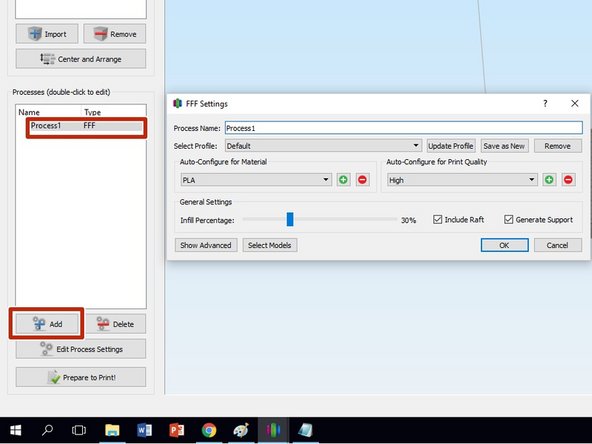

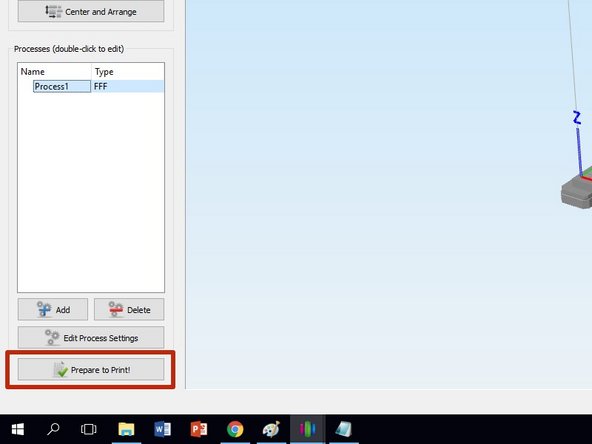

Double click Process1 in the Processes window to bring up the Print Settings dialog. If Process1 does not appear, click Add to generate a new process and open the dialog window.

-

Adjust settings as shown:

-

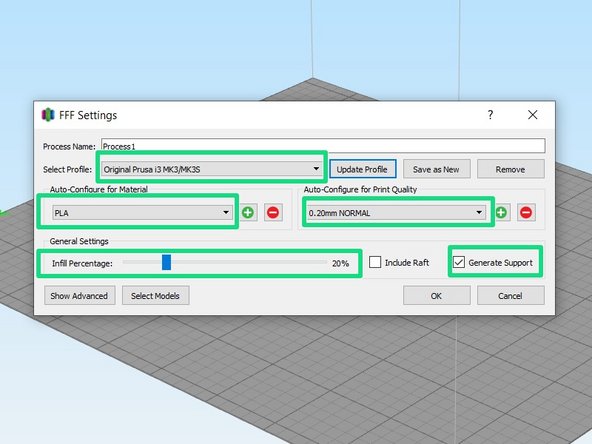

Select the Original Prusa i3 MK3/MK3S profile.

-

Select PLA or PET as your print material in accordance to whatever is loaded on the printer. You can treat PET and PETG as the same thing.

-

Choose to print 0.20mm NORMAL quality. The trade off between Low and High quality comes in the form of quality vs. print time. Generally, Normal results in good prints at reasonable speeds.

-

Set Infill to 20%. This parameter determines whether your part is completely hollow, solid, or somewhere in between. Increasing infill will add rigidity to your part if it must withstand heavy loads. However, this will also increase the print time for your part, and increase the likelihood of warping.

-

Confirm that Original Prusa i3 MK3/MK3S is displayed in the Select Profile field. If this profile is not selected, or not available as an option, quit Simplify3D, log out of the computer, and go back to the beginning of this tutorial and be sure to log in to the computer with the proper credentials!

-

This profile will set the heated bed and extruder to the correct temperatures for the filament you choose. There is no need to adjust the temperatures manually.

-

-

-

Depending on the previous printer used with this computer you may see the print bed on the screen resize and shift. If this happens you should click the Center and Arrange button again to re-center your print!

-

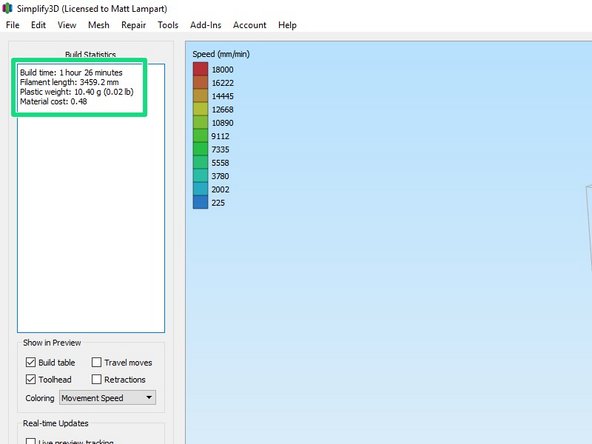

Now click the Prepare to Print button. Simplify3D will show you a preview window detailing the toolpaths used to construct your object.

-

If you see a window asking if you would like to enable support generation, click Yes. This window can be avoided by clicking the "Generate support" option when you are defining the print settings in the previous step.

-

The top left of the screen shows useful build statistics such as build time, filament usage, and cost of material.

-

-

-

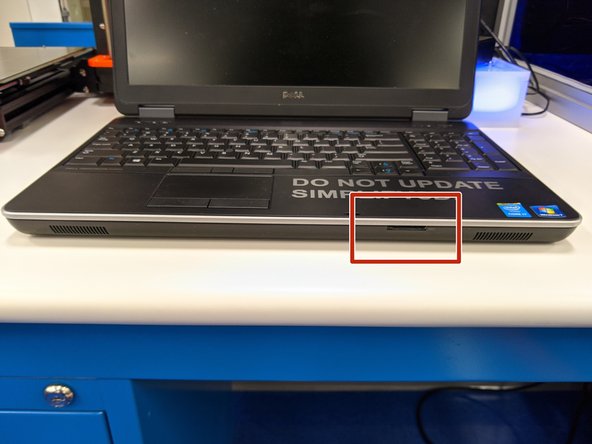

Now you need to transfer the information to the printer. Remove the SD card from the printer control interface, located on the bottom left side of the orange LCD case.

-

Insert the SD into the card reader located on the front of the laptop.

-

-

-

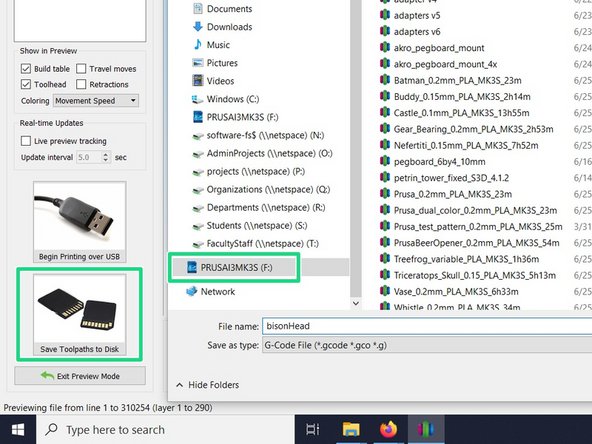

Now click Save Toolpaths to Disk and save your file to the PRUSAI3MK3S (F:) drive.

-

-

-

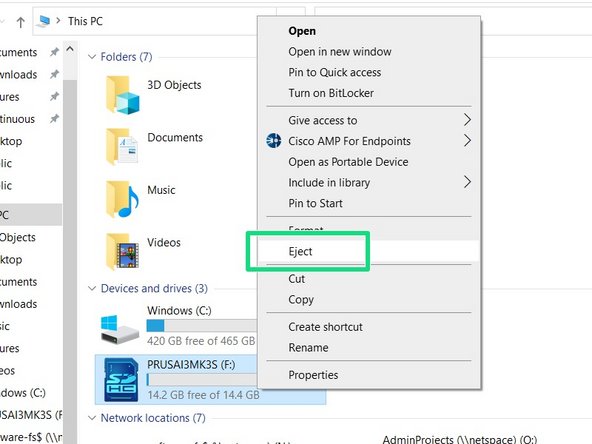

Open a Windows Explorer window and locate the PRUSAI3MK3S (F:) drive. Right click on this drive and choose Eject. Wait until the drive disappears from Windows Explorer.

-

Be sure to eject the SD card properly from Windows. Failure to follow this step can cause the card to become corrupted which will prevent you from printing.

-

Remove the SD card from the laptop and insert it back into the printer.

-

-

-

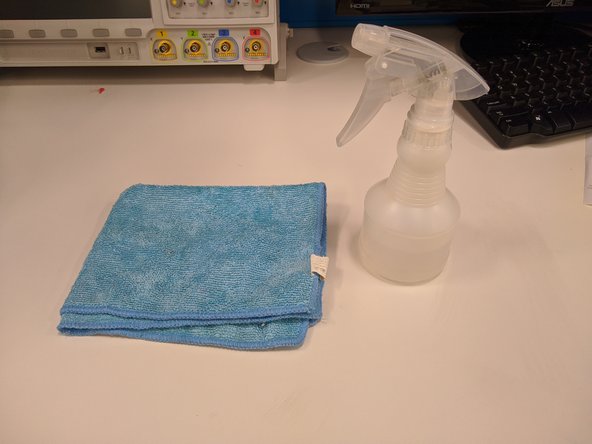

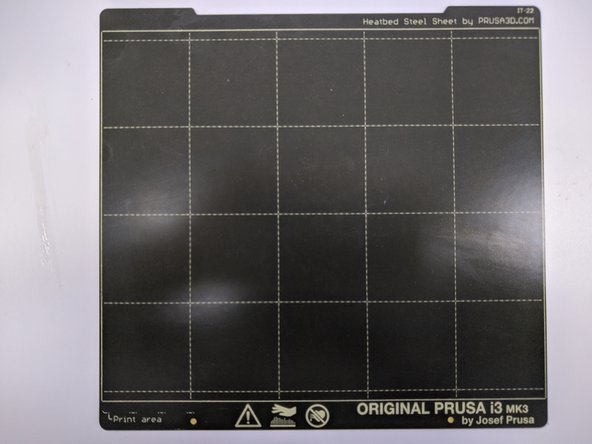

Examine the magnetic print surface. It should be free of all glue residue, previous printer filament, etc. Part of being a responsible member of the Maker community is ensuring tools are ready for the next maker.

-

If you find that there is debris on the print surface you can lift it up by the front left corner and remove it from the printer. Lay the surface on a table and use one of the water spray bottles to spray the surface and wipe clean with a microfiber cloth.

-

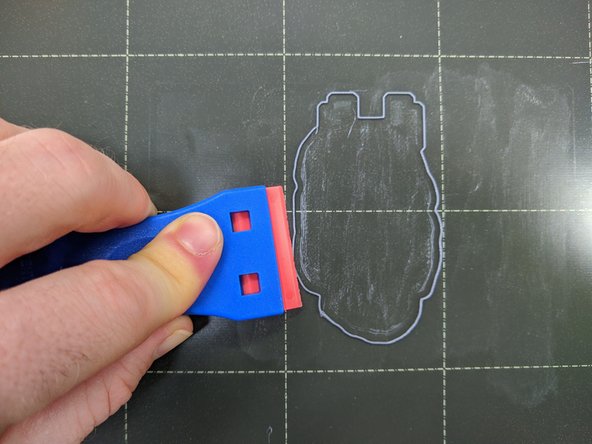

Filament stuck to the print surface can be removed with a plastic scraper.

-

Do not use any metallic tools to remove material from a print surface! Metal tools can scratch and damage the print surface.

-

-

-

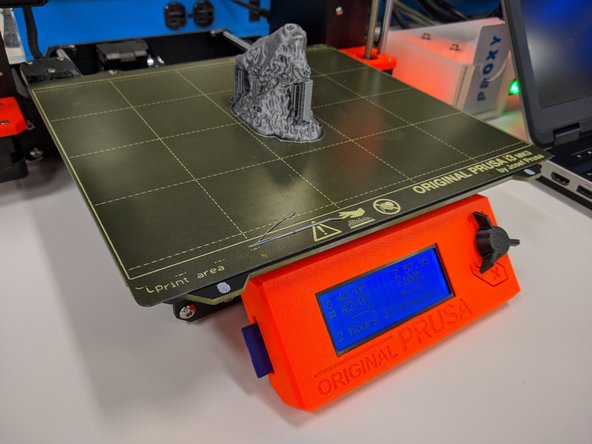

With the SD card loaded you will be presented with a list of gcode files on the LCD. Use the black knob to rotate the indicator arrow until your file is selected. In this case we are printing bisonHead.gcode. Press the scroll knob to select the file.

-

The screen will return to the information display screen and you will see the text, "Bed Heating" displayed at the bottom. You can watch the bed heat to the appropriate temperature and then the hotend will heat next.

-

Once both bed and hotend are up to temperature your print job will begin. The printer will first auto-level by touching off on multiple points on the print surface.

-

-

-

When the print is finished, let it cool for several minutes. The object could warp if it’s handled before cooling. Also, the bed will cool after several minutes, making it safer to remove your part.

-

-

-

!!!STOP!!! It is tempting to just pull your print off the bed, but you can damage the machine or cause misalignment if you try this. Make sure to carefully read and follow the instructions below to remove the print.

-

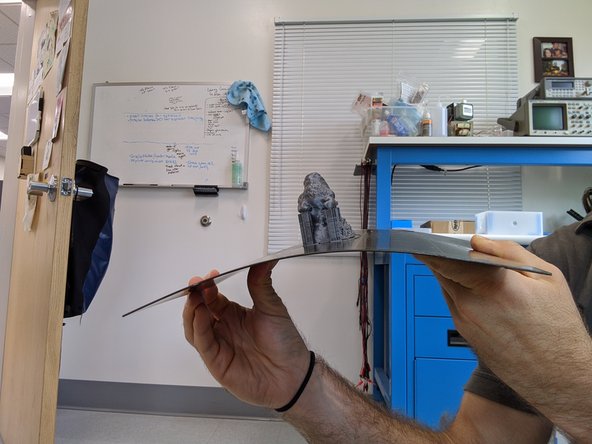

Be careful not to burn yourself, wait a couple minutes before completing this step. Hold down on the edge of the bed and pull magnetic print surface off. Once the print surface (with your print) is removed from the printer then detach the print by gently flexing the print surface.

-

It may be necessary to flex the print surface on multiple axes. You can also try flexing it in both a concave and convex fashion.

-

If your part is particularly difficult to remove from the print bed you can use a plastic scraper to gently pry your part loose.

-

-

-

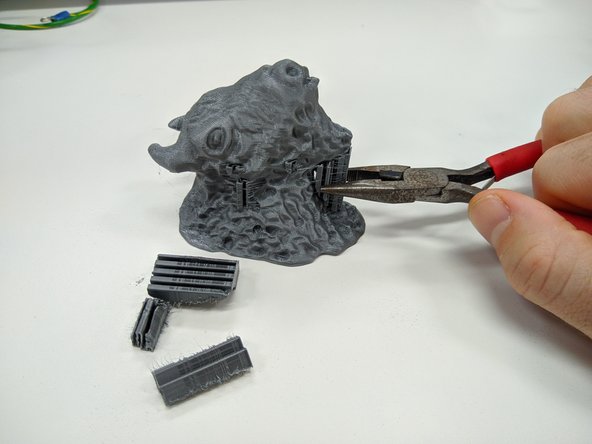

If your part had support material, you may now safely remove it. Use pliers and exercise caution.

-

Again, be careful when using tools to remove support material. Do not let the tools slip which could cause cuts on your fingers and hands.

-

-

-

Remove any remaining plastic from the print bed by using the plastic scraper. The printer will print a skirt, a small ring of plastic, around the perimeter of your part. Be sure to remove this skirt.

-

Clean up any bits of plastic and all of your support material. All of your scraps can go in the trash.

-

Use the vacuum mentioned earlier if there are a lot of small bits of plastic.

-

Use a spray bottle with water to wet the print surface. Next, scrub the surface thoroughly with the provided microfiber cloth to get rid of ALL the remaining glue present on the surface of the bed.

-

At the end of this step, the surface of the bed should be clean and there should NOT be any residue of glue or filament present on the bed.

-

-

-

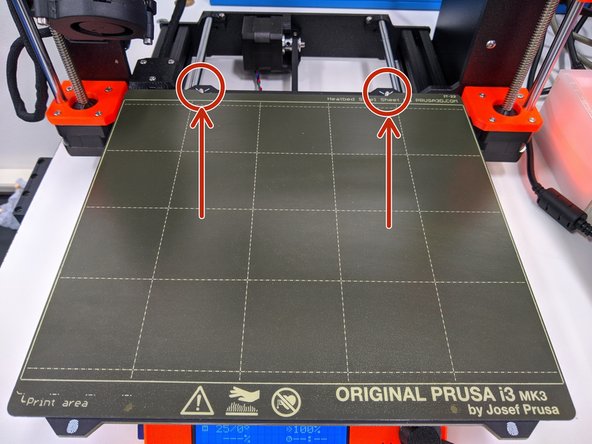

The final step is to place the print surface back on the printer. Use the two locating pins at the rear of the print bed to properly align the print surface.

-

Finally, remove the 3D printer training card from the Portal box. You can silence the beeping by pressing the illuminated green button on the front of the box. The printer should power down.

-

Congratulations on completing your first 3D print!

-

Cancel: I did not complete this guide.

13 other people completed this guide.