-

-

When it comes to material choice in mold making/casting, there is a very large selection.

-

For the purposes of this tutorial, material selection will be limited to Smooth-On or other similar rubber materials, particularly materials which are commonly used in medical and prosthetic applications.

-

Furthermore, this tutorial does not include every situation, and the reader is encouraged to further research this subject before making a decision.

-

This tutorial has been created by Jacob Nickle along with the use of Gemini AI and Microsoft Copilot.

-

-

-

It is important to note that Smooth-on has many resources when it comes to material selection including this link.

-

This tutorial discusses silicone, polyurethane and latex as possible material choices.

-

Other important material characterizations such as hardness, color, viscosity, and ultrasound imaging are discussed.

-

However additional potentially useful material properties such as transparency, ultimate strength, pot life, cure time and so forth are not discussed.

-

It is encouraged to fully research the material properties, look for similar examples, contact Smooth-On support and/or do preliminary testing before making a final decision on a material.

-

-

-

Silicone rubber is a commonly used materials especially for mold making. This is due to the following reasons:

-

Excellent Release - Silicone molds have a naturally non-stick surface, which means release agents are often not needed.

-

Temperature resistance - It can withstand a wide range of temperatures

-

Chemical resistance - It has good resistance to a variety of chemicals, including high-temperature water and chlorinated hydrocarbons.

-

Detail reproduction - It can capture incredibly fine detail and offer low shrinkage compared to other options.

-

-

-

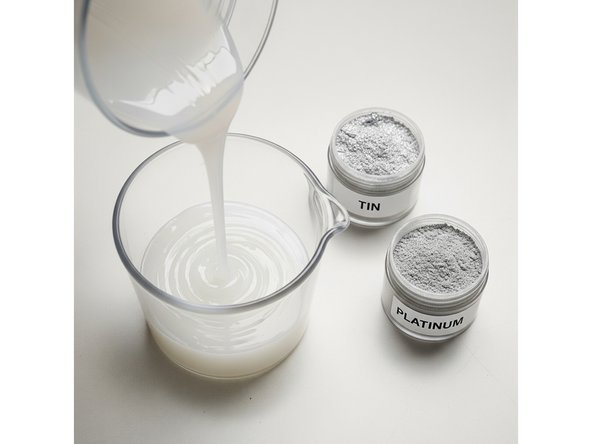

Two common silicone variants are tin and platinum cure. The following characteristics differentiate these variants:

-

Cost - Tin cure is generally lower in cost than Platinum cure

-

Cure Inhibition - Tin cure is very resistant to cure inhibition. Platinum, however, does have cure inhibition when in contact with sulfur, tin and other contaminants.

-

Shrinkage - After curing, tin cure shrinks 0.3%-0.5% whereas platinum only shrinks less than 0.1%.

-

Library Life - After the silicone is cured, tin cure lasts 1-5 years whereas platinum cure lasts much longer.

-

Food/Skin Safe - Tin cure is not recommended for food and skin safety whereas platinum cure is generally safe. Always check the technical data sheet for safety information.

-

-

-

Urethane rubber has the following advantages and disadvantages:

-

Cost - Generally less costly than silicone rubber.

-

Hardness variability - compared with silicone, urethane rubber has a wide range of hardness.

-

Release - Urethane rubber adheres to most surfaces, so a release agent is usually required.

-

Moisture sensitivity - when using within a humid environment, it can bubble and have other undesirable effects.

-

Shrinkage - Can be slightly higher than silicone rubber.

-

Food/Skin Safe - Urethane rubber is not recommended for food or continuous skin contact.

-

-

-

Latex has the following advantages/disadvantages:

-

Cost - One of the least expensive mold-making materials available.

-

Extreme Flexibility - It offers exceptional elasticity and stretch, making it easy to demold parts with complex undercuts without tearing.

-

Application Process - It must be brushed on in many thin coats, which is a very time-consuming process.

-

Shrinkage - Latex molds will shrink as they cure and over time, making them unsuitable for projects that require high dimensional accuracy.

-

Allergies - It contains natural proteins that can cause allergic reactions in some people. Do not use latex within Bucknell labs without permission.

-

-

-

Durometer is a measure of the hardness of a material, specifically its resistance to indentation. It is a standardized, dimensionless value used for materials like rubber, plastics, and other elastomers.

-

Because the hardness of materials varies so widely, different scales are used to provide accurate and meaningful measurements for different types of materials.

-

For example, a pencil eraser has a shore hardness of 50A whereas a golf ball has a shore hardness of 50D.

-

A higher number indicates a harder material, and each scale (shore A vs shore D) can have a different hardness but the same number.

-

An average durometer value for human skin is difficult to identify because of many contributing factors. However, a value of 32 in the Shore O scale was found in this paper with a population size not indicative of all human skin because of variation in age, measurement location, health and so forth.

-

A value of 32 in Shore O hardness scale is roughly equivalent to between 5 and 10 on the Shore A scale. There is no direct mathematical conversion between scales.

-

-

-

To add a uniform color to a silicone rubber, add Silc Pig before using to cast. This product is used with Dragon Skin, Ecoflex and Mold Max T series. Slic Pig is also skin safe when used in the appropriate quantity.

-

When a surface non-uniform color is needed, use Psycho Paint.

-

When realistic wounds are needed, use Skin Tite. However, note that silicone adhering to silicone can become an issue.

-

For the strongest possible bond, the surface of the existing silicone model should be cleaned thoroughly with a solvent like isopropyl alcohol (IPA) to remove any oils or contaminants. The surface should be completely dry before applying the new silicone.

-

If the surface is very smooth, it may also be helpful to "abrade" or roughen it slightly with a coarse brush or sandpaper to give the new silicone a better mechanical bond.

-

-

-

Viscosity highly influences the ability of liquid silicone to flow into small, confined areas.

-

The thinner the liquid silicone, the better able it is to capture detail. The following tips may be helpful in reducing the viscosity:

-

Temperature - Increasing temperature will generally lower the viscosity. However, changing temperature affects the pot life and cure time.

-

Additives - There is a smooth-on Silicone Thinner product. There is also a additive for thickening silicone products. Be aware that these products also change pot life, hardness, vacuuming needs and so forth. Test these additives before making a choice.

-

The general reference is that under 1000 cps is ideal for fine detail whereas 1,000- 10,000 is for general use.

-

Note that vacuum degassing or pressure casting also helps liquid silicone to capture higher details.

-

-

-

Smooth-on has good recommendations and examples for medical simulations as linked here.

-

In general, skin safety and color are requirements which limits Smooth-on products to the Dragon Skin and Ecoflex series.

-

-

-

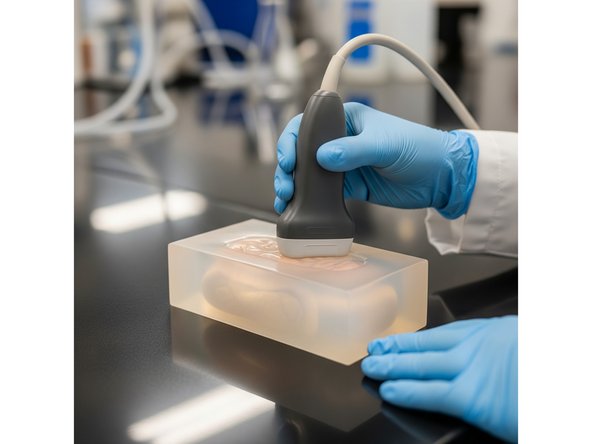

Occasionally silicone mimicking human tissue is used along with an ultrasound imaging for medical simulations. These are called medical phantoms.

-

-

Air within the silicone largely affects the utility of ultrasound imaging. It is recommended to fully vacuum the liquid silicone before pouring into the mold, reducing the viscosity to reduce the need for vacuuming, or a combination of the two.

-

Additives such as graphite, cellulose or glass microspheres introduce echogenicity to help distinguish different regions of the image and/or to create speckled appearance of real tissue.

-

Smooth-on itself states that its products have had moderate results when used to make medical phantoms.

-

There are other materials that may work well with ultrasound imaging such as synthetic medical gel (Humimic gel), gelatine powder or other similar material. Use of these materials depends on many factors such as casting temperature, self life, skin contact safety and so forth.

-

Almost done!

Finish Line