Introduction

This guide is a concise compendium of information for projects using the Thunder Laser. After completing this tutorial you will have learned how to use the Thunder Laser for simple project by making a key chain.

Tools

Parts

No parts specified.

Featured Document

-

-

The Thunder Laser is located in the MakerE in Dana 111.

-

-

-

Any use of a laser cutter is potentially hazardous. Materials can catch on fire, disabling machine interlocks can potentially expose you to laser radiation capable of blinding you, and cutting the wrong materials can release toxic gasses.

-

Before you start cutting know where the fire extinguisher is in case materials catch on fire.

-

If you are unsure if a material is safe to cut, ask first. Many plastics contain chlorine or fluorine and materials like PVC, vinyl records, and Teflon are never safe to cut.

-

You must keep an eye on the laser cutter during any cuts in case there is a fire. Leaving the immediate area during a cut is a violation of the MakerE User Agreement and may result in penalties up to permanent expulsion from the space.

-

-

-

Check the bin near the Thunder laser first to see if you can use has already used material. It is wasteful to always use fresh stock when working on a project. Whenever possible you should sort through the used stock in the blue bin underneath the plywood table.

-

For this project you will need a piece of material with an area about 3" x 3" square.

-

Grab a ruler and measure the remaining areas on scrap material to see if your project will fit on one or more pieces of scrap.

-

If your work is too large to fit on scrap then feel free to use new stock located on the shelves near the laser cutter.

-

If you are doing preliminary cuts or simply testing a design we recommend using cardboard rather than wood or acrylic. It is cheaper and faster.

-

Again, if you are not sure what is safe to cut, check with a MakerE Tech!

-

-

-

Every user should check the following before turning on the Thunder Laser:

-

Make sure the switch on the chiller unit below the laser is turned to the on (I) position.

-

The cooler won't turn on until the laser turns on.

-

MakerE Techs: Every week check the back of the chiller to make sure the water level is in the green region. If it is not stop you will need to fill the chiller with distilled or RO water.

-

Only after you have checked the switch and made sure it is on are you ready to turn on the laser cutter.

-

-

-

Before you turn on the Thunder Laser make sure your access card is in the Portal Box and it is green.

-

Do NOT start the LightBurn software yet since it may throw an error if it cannot find the laser. You must turn the laser on before starting the software.

-

Turn on the Thunder Laser using the Main Switch which is the upper of the two switches on the right side of the machine.

-

DO NOT turn on the lower Laser switch yet since that turns on the laser tube. For safety leave it in the off (O) position for now. This is due to the high voltage of the laser

-

Once the machine is on you can move the laser head by using the four arrow buttons shown. The two other arrow buttons move the bed up and down.

-

Move the laser head to the back, left position and drop the bed so you can load your material without hitting the laser head.

-

-

-

Cutting settings are in the PDF document attached to this guide and near the laser. Scroll to the bottom to access the file.

-

If your material isn't listed, talk to a maker-e tech before proceeding. Using the wrong settings can cause a fire!

-

Note that different laser heads will affect cutting power and speed so verify which head is currently on the laser before cutting. The spot size and focal lengths vary.

-

The standard head is for most cutting and has a laser spot size of 0.0039 inches or 0.1 mm and focal length of 5 to 6.5 mm.

-

The 4 inch head is to cut materials over 10 mm thick and has a laser spot size of 0.008 inches or 0.2 mm and a focal length of 9 to 11 mm.

-

The high resolution head is for engraving photos up to 1000 lines per inch. It will only cut materials 1 mm thick or less, has a 0.002 inch or 0.05 mm focal spot with a 3-4 mm focal length.

-

If the head on the machine works for your job skip ahead to step 8, otherwise change the head as described in the next step...

-

-

-

You will want to use the standard nozzle for almost all your cutting so if that nozzle is installed you can skip this step.

-

If you need to change the head, consult a maker-e tech first. Do NOT do it by yourself

-

-

-

If you haven't done it already, use the arrow keys or origin button to move the laser head to the back of the unit.

-

Slide the material into the laser bed

-

Be careful! Do not bump the laser head

-

Check to make sure your material is totally flat- every part of the material should be touching the laser bed. Otherwise, the laser won't cut through

-

Use the magnets on the side of the laser cutter to hold the material flat.

-

The magnets are quite strong, so make sure not to stick them together!

-

If you use magnets make sure they are out of the path of the laser head!

-

-

-

Always make sure to check the laser focus!

-

Use the arrows shown in the picture to move the bed up or down

-

Grab the acrylic focal tool and try to slip it between the laser head and the material

-

If the gap is larger than 5 mm, use the arrows and move the bed up

-

If the gap is smaller than 5 mm, twist the brass knob until the laser head loosens and move the head until it touches the acrylic piece. Re-tighten the knob.

-

This sets the focus properly - remove the focus tool and you are ready to go!

-

-

-

Begin by inserting an authorized makerspace card into the Portal box BEFORE launching the software.

-

Login to the computer next to the laser cutter using the credentials stuck to the computer

-

Open the LightBurn software from the computer desktop. The icon has a dragon on it

-

For this tutorial we will create a Bison keychain fob. Click to download the Bison Keychain file.

-

I chose to make this one out of leather, but you can choose whatever material you wish.

-

Note that the laser cutter can process vegetable tanned leather but not chrome-tanned (often colored) leather since it will release toxic chemicals!

-

-

-

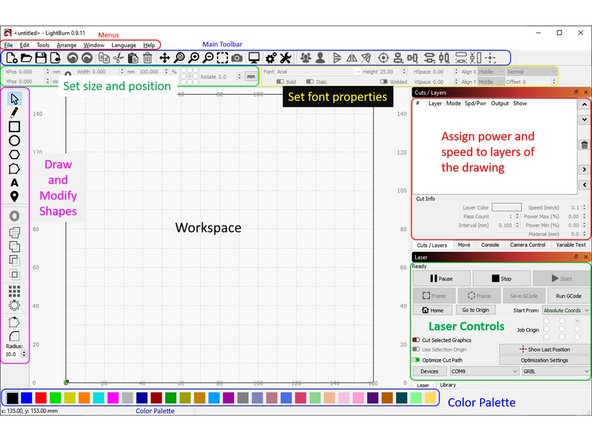

The Lightburn software interface is somewhat intimidating, since it supports a lot of features. The next few steps will walk you through the basic steps of cutting and engraving. For a more in-depth exploration see this tutorial.

-

The image shows the various parts of the Lightburn software work area. To import then engrave or cut your project you will have to:

-

Import a .svg file for cuts and engraves, or an image file if you just want to engrave using the file menu.

-

Make any modifications to the file such as changing the size, adding text or shapes, etc. using the tools on the left of the screen.

-

-

-

Use the File → Import menu to load the keychain .svg file.

-

If you would like to create a different design that is discussed in the next step.

-

Different colors tell the laser to use different speeds and powers.

-

-

-

If you would like to use your own image for the keychain then import the image into Lightburn. It should be high contrast black and white or greyscale, and sized to fit on the keychain you would like to make.

-

After the image is loaded, use the box or circle tool in LightBurn to make a border around the image. This will be the outer diameter, which is cut by the laser.

-

Make sure to leave room for a hole for the keychain to go through.

-

Add a hole about 0.2 inches in diameter inside the border.

-

Change the color of the border by using the select tool (arrow at the top of the left tool bar) to select part of your drawing then the color palette at the bottom to set the color.

-

If you cannot select just the outline, then you will have to go back and fix your file before you can cut.

-

Do the same for the hole, using a third color that is different than the image or the border, in this case green.

-

-

-

Doing a successful cut or engrave depends on setting the right cutting power and laser head speed.

-

The linked PDF document has suggested power and speed settings for common materials for this particular laser cutter (Nova 24). You should open this now to make sure your settings are correct! Download the speeds and settings guide.

-

There are settings for engraving images and separate settings for cutting materials. Make sure you choose the right ones!

-

Materials are not ideal so these settings are good starting points but won't always work. Plywood or MDF particularly have a lot of variation between pieces. We recommend doing a small test cut or engrave and dialing in settings before starting a big project!

-

Not all materials can be processed on a laser cutter and some materials such as PVC plastic or chrome-tanned leather can release toxic and/or corrosive chemicals. DO NOT cut any materials you are unsure of. Check with a MakerE tech first!

-

-

-

Once you have your file in Lightburn and all the various parts that need different cut speeds and powers in different colors, the next step is to assign powers and speeds to each layer.

-

Find the Cuts/Layers menu window shown in the figure. If it is not visible, then open the Windows menu at the top and make sure it is selected. If it is unchecked, then check it again and it should appear.

-

In the menu window you will have one line for each of the layers (colors) in your figure. On the first figure there are three layers: blue, red, and black.

-

To set the power and speed for each layer. double click on each entry in the Cuts/Layers menu window and set the correct power and speed from the PDF guide. This is shown in the second image.

-

Check that the laser and air assist boxes are checked for each layer. Double check that the material settings are correct!

-

-

-

Each cut/engrave is represented by a different color and layer. Before beginning your cut you will have to make sure the order of cuts and engraves is correct.

-

The order in which each layer is cut is very important. The layer (color) at the top will be cut first, and the one on the bottom last.

-

The correct order for cuts is described as follows:

-

Engravings should be done first, so it should be at the top of the list.

-

Next should be any interior cut out (holes, windows, etc.)

-

The last layer should be the outline

-

To change the layers, select the layer to move and use the up/down arrows on the screen to set the order

-

You can switch between the Layers menu and the Laser menu using the tabs, as shown in the second image.

-

-

-

Make sure any outlines that will disconnect the piece you are cutting out from the main body of your material are *last* in the cutting order.

-

Cutting the piece out first may cause it to move midway through cutting, ruining the project.

-

Small pieces may even be blown out of the path of the laser, potentially getting stuck and then hit by the laser head.

-

Make sure that the Mode setting (see second image) matches what you want the laser to do. Cuts should be set to "Line" and engraves to "Fill".

-

If the line on your drawing is thick and the mode is set to fill, the laser may do multiple cuts, which creates a fire hazard!

-

Close the lid of the laser!

-

-

-

This is a very important step which if not followed can ruin your project or waste material!

-

In LightBurn, check that the origin position is set to user origin

-

Use the arrow keys on the laser to move the head to wherever you want the origin to be

-

Try to position the origin so that you use as little material as possible!

-

Press the origin button on the laser to set the origin

-

-

-

Once the origin is set, hit the frame button in LightBurn.

-

After you hit the button, the laser head will trace the outer bounds of your cut.

-

If the bounds exceed the size of the material, try to find a bigger piece of material!

-

If your part is larger than the bed size, you'll need to use the laser cutters in the Mooney lab or 7th Street makerspace

-

-

-

The laser can catch materials on fire! DO NOT LEAVE THE AREA.

-

Double check the origin and frame area!

-

When you are sure everything is ready and the lid is closed. Hold Shift on the keyboard and simultaneously press the Send button and the laser should immediately start cutting.

-

If the laser does not start. hit the brown start button on the laser, as shown in the image

-

Some materials will flare up with small flames or char. Usually the air assist blows these out.

-

If there are larger flames or the fire starts to spread, hit the emergency stop button and put out the fire with the nearby fire extinguisher!

-

-

-

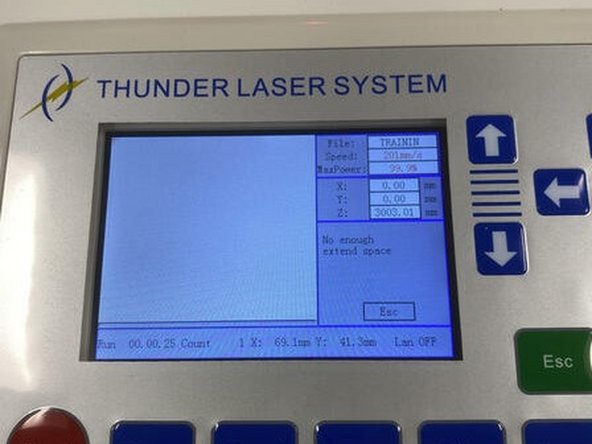

The "No enough extend space" error might show up, and that's because there's not enough space for the cutter to accelerate/deaccelerate.

-

Try one or multiple of the following: 1. Move the image closer to the center. 2. Make the image larger. 3. Slow down the speed

-

-

-

The laser should do any engraving first followed by cuts if you got the layers set in the right order. The video shows the laser etching the surface of leather for the keychain project.

-

After the cut is finished the laser head will move back to the set origin.

-

Wait for any smoke to clear, then lift the lid and remove the design. Make sure not to hit the laser head along the way! Use the control panel buttons to move the laser head or drop the bed if you need to.

-

Turn off the laser switch.

-

If you are working with wood, there is a good chance that as you move the design/material, you will see smoke. Do not worry too much about this.

-

-

-

When your design and the excess material has been removed, place the excess in the scrap bin, unless you are using your own material or there is no good space left on the sheet you used.

-

Clean the bed of the cutter for other people to use in the future. Make sure any pieces of material that are stuck in the grid get pushed out to avoid a fire hazard!

-

Close the lid of the cutter and double check to make sure it is turned off when you are done cleaning up. Remove your maker card from the portal box

-

Do not turn the cooler off!

-

-

-

Congratulations! You have just cut out your first design on the Thunder laser cutter!

-

Show your keychain fob to one of the MakerE Techs and ask them to certify you for using the ThunderLaser.

-

See some of our other tutorials for more advanced cutting and engraving ideas.

-

-

-

ONLY MAKER-E TECHS ARE AUTHORIZED TO CHANGE THE AIR AISSIST!

-

For most cutting jobs this step is optional since the airflow will already be set correctly. If you need to set the air flow continue reading, if not skip to the next step.

-

In some cases where you are cutting particular materials or engraving at high resolution, you may need to set the amount of air coming out of the laser head.

-

Air flow is set by turning the knurled shafts at the bottom of the Air-assist Control on the left side of the laser as shown in the photo.

-

Turning the knob CW reduces the amount of airflow, turning it CCW increases the amount of air.

-

You generally want to use high volume on the air assist for cutting, and low volume for engraving.

-

Setting which air assist is used in the LightBurn software is covered in this video. Basically if you turn air assist off in software it uses the low pressure, turning it on in LightBurn uses high flow.

-

Cancel: I did not complete this guide.

13 other people completed this guide.