-

-

This filament changing tutorial is intended only for the Fusion3 EDGE printer in the fabrication lab (ACET 237). Other printers may require different instructions.

-

This tutorial only works for commonly used filament such as PLA, PETG and ABS. If an engineering-grade filament requiring higher temperatures or a flexible filament needs to be loaded, ask the lab director for assistance. This tutorial does not cover the needs these specialized filaments have.

-

-

-

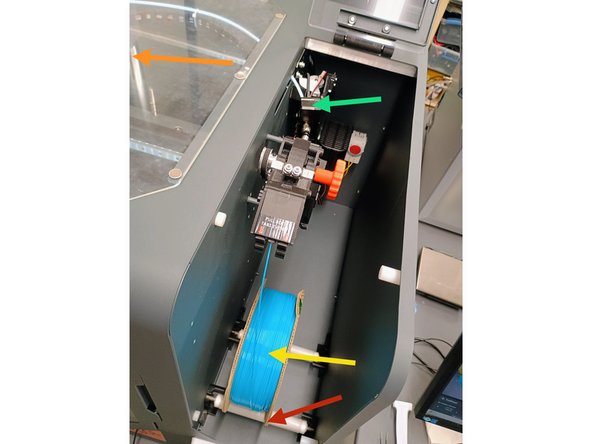

Filament is defined as a thin (typically 1.75 mm in diameter) polymeric extrusion that is typically wound onto a spool.

-

A spool is a plastic cylinder which conveniently stores wound up filament.

-

A filament sensor notifies the printer when filament has run out or is not properly feeding through the extruder / hotend.

-

An extruder is a stepper motor and other hardware that drives the filament through the hotend.

-

The hotend heats up the filament until it can be extruded through a nozzle.

-

Note that the colors in the images correspond to the definitions.

-

-

-

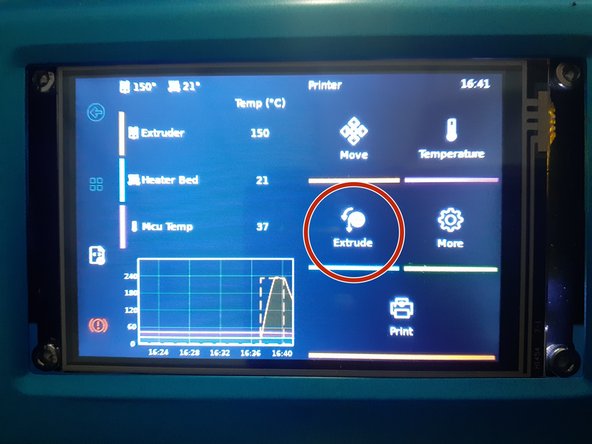

On the Fusion3 EDGE touchscreen, select "Extrude"

-

If the printer is paused, select the back arrow found on the top left of the screen.

-

Select "Unload".

-

Wait until the hotend reaches the target temperature and the filament is automatically pulled out of the extruder.

-

The extruder will start backing out the filament. Gently roll the spool backwards so that the filament remains tight.

-

Once the automated unloading procedure is finished, pull out the filament.

-

Remove the spool of filament from the holder.

-

Secure the end of the filament through the side holes of the spool as shown in the third image.

-

-

-

Grab another spool of filament.

-

Take the end of the filament out of the holes that secured it.

-

Cut the end of the filament at a 45° angle.

-

This can make feeding the filament through the tube, extruder and hotend easier.

-

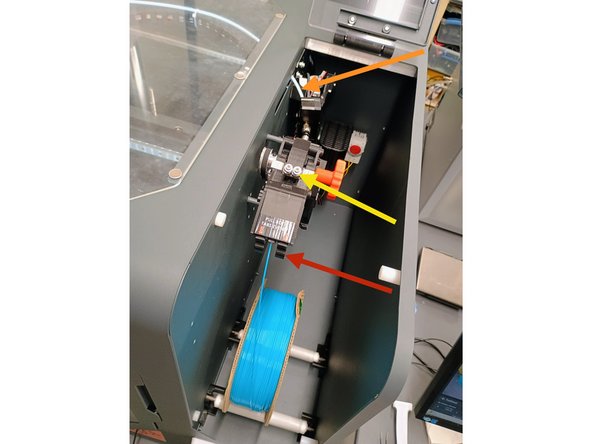

Place the new filament spool on the holder in an orientation such that the filament can easily feed through the filament sensor. Reference the 2nd image as needed.

-

-

-

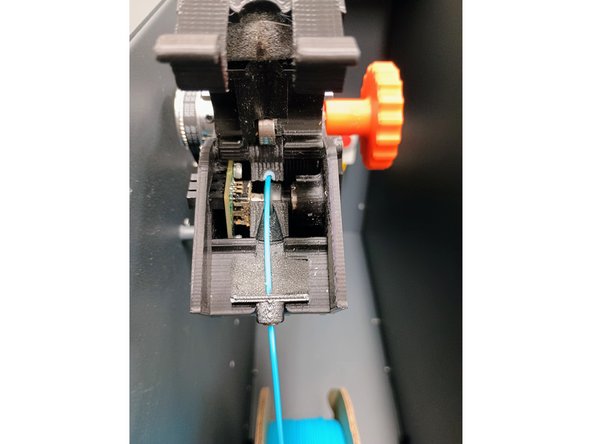

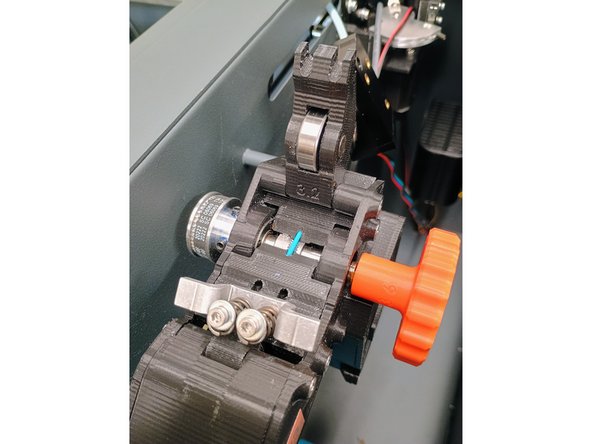

Thread the filament through the extruder using the following steps and image as a reference.

-

Pull tabs (red arrow) revealing internal area.

-

Feed the filament through the entrance hole and through the next hole now visible, as seen in the second image.

-

Pull forward the spring-loaded metallic handle (yellow arrow) and open the plastic part revealing the gripping gear as seen in the third image.

-

Feed filament through this area.

-

replace plastic part and metallic handle as before as well as the tabs that were opened at first.

-

Rotate the orange knob where the top of the knob is moving forward (clockwise) until the filament passes through the filament sensor all the way to the orange arrow (about 2 mm past the filament sensor).

-

-

-

Select 'Extrude' on the touchscreen

-

Select 'Load'.

-

Wait for the nozzle to heat up.

-

Watch for the polymer to extrude out of the nozzle to verify that the filament has been successfully loaded.

-

The print can now be started or resumed.

-

If there are any issues, contact the Lab Director for assistance.

-

Almost done!

Finish Line