-

-

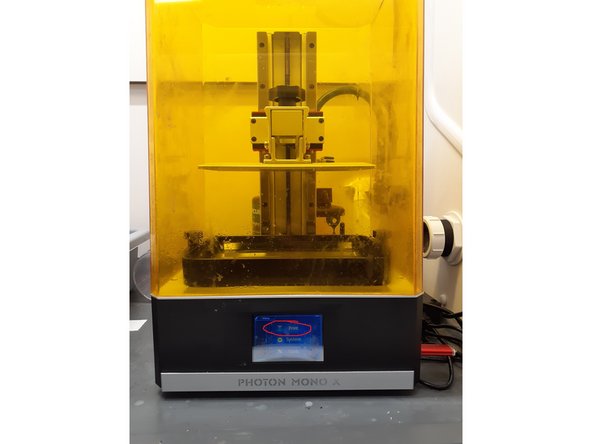

Anycubic Mono X is a LED based SLA resin printer. Unlike the FormLabs, each layer is cured all at once using an LED screen to cure each layer

-

When compared to FDM printing, SLA printing has better resolution and less noticeable layer lines. Ask the Lab Director to know if resin printer is best used in your project

-

This tutorial will teach only the basics of resin printing to get you started and is not an all-inclusive guide to resin printing

-

It is assumed that the user has a 3D stl model that fits within the build volume of the printer

-

-

-

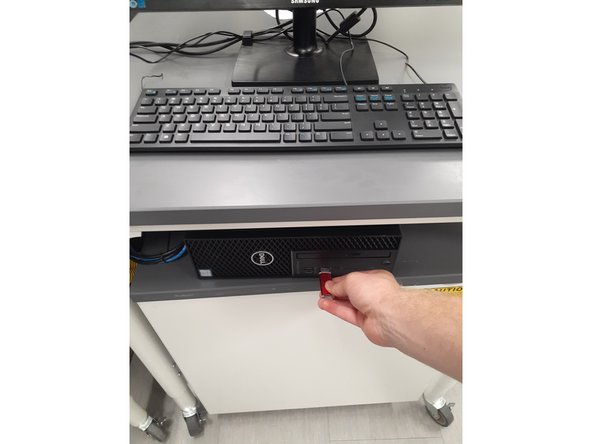

Log onto the BME computer in the Fab Lab using credentials provided at the top of the screen

-

Open the Chitubox slicer software

-

Import stl file into Chitubox

-

-

-

Further information than given in this tutorial can be found here.

-

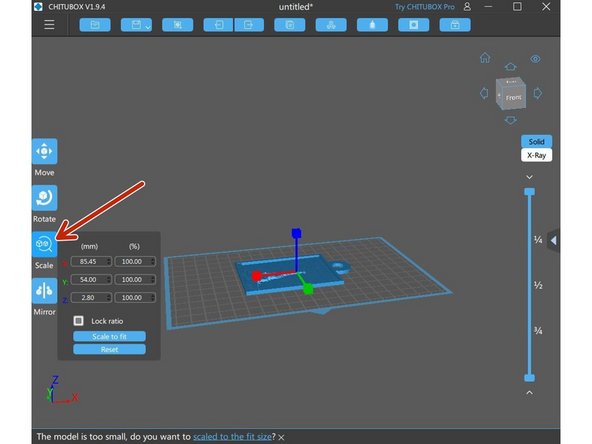

Roughly verify scaling of part by visually identifying size of object on the screen. If needed, scale your part

-

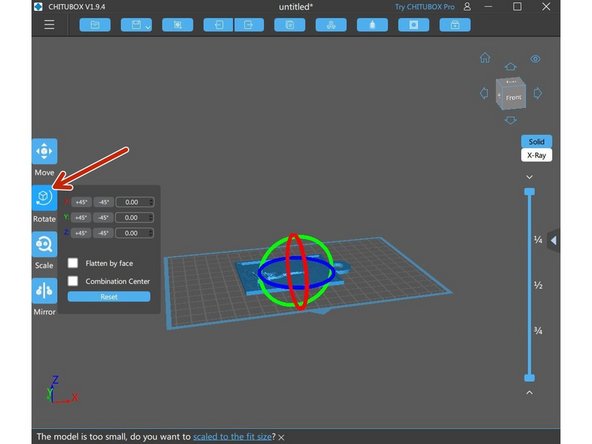

Rotate your part as needed. Note that you are able to select a surface that you want on the build platform.

-

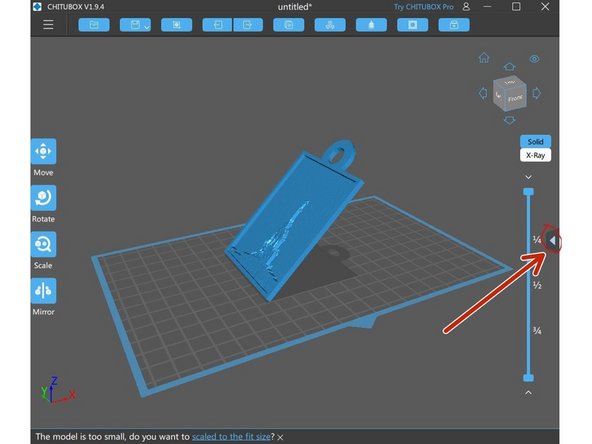

Open further model settings using arrow in picture(right center of screen) if not already open

-

-

-

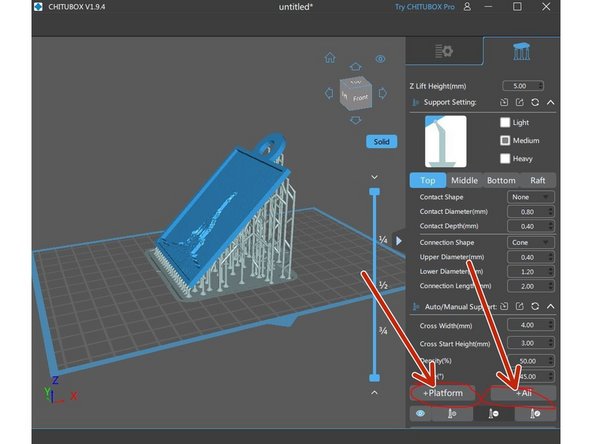

open up support material / platform generation tab

-

Support material is used to support your model in areas that would otherwise not stick to the build plate

-

Platforms are used so that support material can stick to the built plate more effectively and so that the model can be removed more easily

-

Autogenerate supports and platform using the +Platform/+All buttons

-

-

-

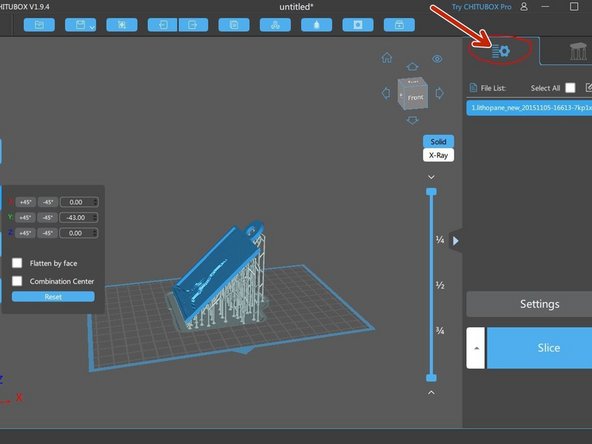

Once you are satisfied with your print, return to the main view by selecting the left tab

-

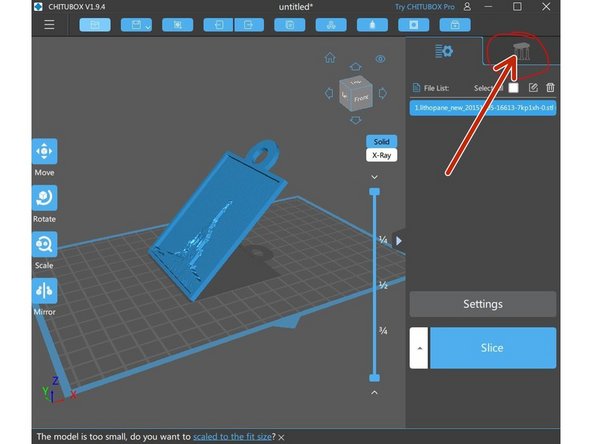

Slice print by selecting the blue "Slice" button

-

Verify that the print looks as you expect it to

-

-

-

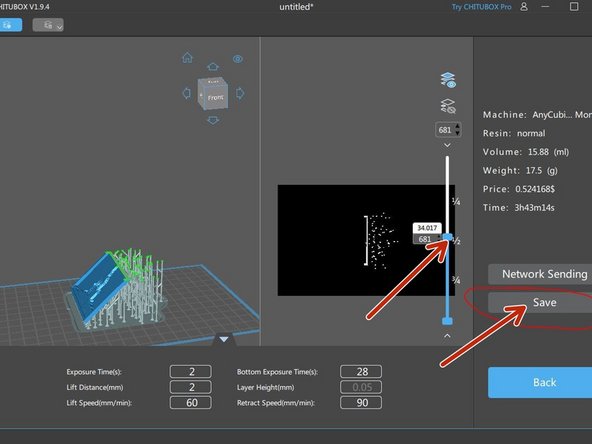

Take USB from the Anycubic resin printer

-

Insert USB in Fab Lab computer

-

Select "Save"

-

Save file in USB

-

Safely eject USB using the "^" on the bottom right of screen, right clicking USB icon and selecting eject.

-

Remove USB from computer and put back into the Anycubic resin printer

-

-

-

Verify build plate is secure and there is a sufficient quantity of resin

-

If you need to put more resin in, you can use the Phrozen ABS-like resin. If you have questions or need to change to a different type, please ask the Lab Director

-

To start the print, press start, select file and press play

-

-

-

Once the print is complete, the next step is to put on gloves

-

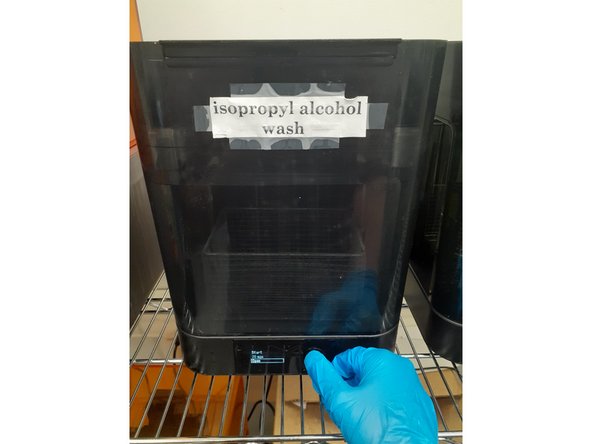

Open the Formlabs isopropyl alcohol wash station closest to the Formlabs resin printer

-

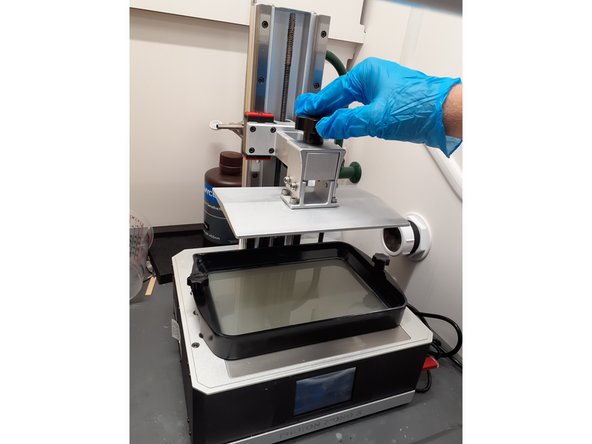

Remove transparent cover on the Anycubic printer

-

Grab a paper towel to prevent resin from dripping anywhere during the next two steps

-

Loosen build plate as shown by unscrewing hand screw

-

Place build plate within basket such that it will not scrape the sides of the wash station when closing

-

Wash for 20 minutes

-

-

-

After washing the print, again put on gloves

-

Open wash station and carefully remove the print from the build plate

-

Replace build plate on Anycubic remembering to tighten hand screw

-

Open transparent cover of cure station and place washed print in center

-

Add desired cure time. 10 - 15 minutes is typical

-

Start curing print

-

Once your part is cured, it is ready to use

-

Almost done!

Finish Line